SY PLASTIC ENGINEERING

Huzhou Shengyi New Material Technology Co., Ltd. is a leading company in the field of engineering plastic products. We specialize in providing exceptional services and establishing long-term partnerships with our clients. At Huzhou Shengyi, we possess in-depth knowledge of the plastic industry and have extensive expertise in PTFE machinery. Our team's wide-ranging knowledge and experience enable us to offer comprehensive solutions tailored to your specific needs. Here are three key advantages that set us apart: 1. High-Quality Products: We take pride in providing top-notch raw materials for plastic products. Our range includes a variety of special engineering plastics such as PTFE, PEEK, PVDF, PI, PPS, and PEI, as well as general engineering plastics like PA6, PC, and POM. We also provide general plastics such as PP, HDPE, UHMW-PE, PMMA, ABS, and PVC. Additionally, we offer composite plastics like Bakelite, synthetic stone, and epoxy resin sheets. These materials are carefully selected to meet rigorous quality standards, ensuring reliability and durability in your applications. 2. Expertise in PTFE Machinery: In addition to our proficiency in plastic products, we specialize in PTFE machinery. We have a deep understanding of PTFE processing equipment and can help you choose the best PTFE machine for your manufacturing processes. Our team guides machine specifications, installation, and maintenance, ensuring optimal performance and efficiency in your PTFE production.

ABOUT US

At SY-Plastic Engineering, we are pioneers in plastic engineering, dedicated to providing innovative and high-quality solutions to meet diverse industrial needs. Founded on a commitment to excellence, our company specializes in designing, developing, and manufacturing a wide range of plastic components and products. Our experienced team of engineers and technicians harnesses cutting-edge technology and advanced manufacturing techniques to ensure that every product meets the highest standards of precision and durability. We take pride in tackling complex engineering challenges and delivering custom solutions that enhance performance and efficiency. Sustainability is at the core of our operations.

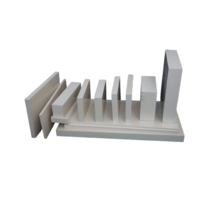

PTFE

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer renowned for its remarkable non-stick and chemical-resistant properties. Often recognized by Teflon, PTFE excels in applications requiring low friction and high durability. It operates effectively across a broad temperature range, from -200°C to 260°C (-328°F to 500°F), making it suitable for extreme conditions. Its resistance to virtually all chemicals and excellent electrical insulating capabilities ensure that PTFE is indispensable in chemical processing, electronics, and automotive industries. Its unique properties also make it an ideal choice for sealing, lining, and coating applications, enhancing performance and longevity.

PVDF

PVDF, or Polyvinylidene Fluoride, is a high-performance thermoplastic known for its outstanding chemical resistance and mechanical strength. With excellent thermal stability and electrical insulating properties, PVDF is widely used in industries such as chemical processing, pharmaceuticals, and electronics. Its versatility makes it ideal for demanding applications.

PCTFE

PCTFE, or Polychlorotrifluoroethylene, is a type of fluoropolymer known for its excellent chemical resistance, low friction properties, and high thermal stability. It is commonly used in applications that require resistance to harsh chemicals and environments, such as in the chemical processing, aerospace, and electronics industries.

PCTFE has a high melting point and is non-flammable, making it suitable for high-temperature applications. Its low permeability to gases and liquids makes it an ideal material for seals and gaskets. Additionally, PCTFE is often used as a coating material to enhance the performance of various substrates.

Overall, PCTFE is valued for its durability, versatility, and ability to maintain performance in extreme conditions.

PEEK

PEEK, or Polyetheretherketone, is a high-performance thermoplastic known for its exceptional strength, stiffness, and chemical resistance. It maintains its structural integrity at elevated temperatures, up to 250°C (482°F), and exhibits outstanding resistance to harsh chemicals and radiation. These properties make PEEK highly suitable for demanding applications in aerospace, automotive, and medical industries. Its excellent dimensional stability and low friction characteristics contribute to its use in precision components and high-stress environments. PEEK also offers good wear resistance and is often used in parts that require durability and reliability, making it a preferred choice for advanced engineering applications.

Plastic Engineering

Plastic engineering is a vital field within materials science that focuses on the design, development, and manufacturing of plastic products. It involves understanding polymer chemistry, processing techniques, and the mechanical properties of plastics. Engineers in this field work on a range of applications, from consumer goods to industrial components, ensuring that plastic materials meet specific performance criteria. They employ methods like extrusion, injection molding, PTFE Sheets & Rods, PVDF, PPS, PFU, PFA, and blow molding to create precise and functional items. Additionally, plastic engineers are involved in improving sustainability by developing recyclable materials and optimizing production processes to reduce environmental impact. Their work is crucial for innovation and efficiency in various industries.

General & Composite Plastic

General plastic products encompass a wide range of items made from synthetic polymers, including containers, packaging materials, and household goods. These products are typically manufactured using extrusion, injection molding, and blow molding. Composite plastic products, on the other hand, combine plastics with other materials, such as fibers or fillers, to enhance their properties. For example, fiberglass-reinforced plastics offer increased strength and durability, making them ideal for automotive and aerospace applications. Both types of products are integral to modern manufacturing, with general plastics providing versatility and cost-effectiveness, while composites deliver advanced performance for specialized uses.

CNC Plastic

CNC plastic machining utilizes Computer Numerical Control (CNC) technology to cut and shape various types of plastic materials precisely. This process ensures high accuracy and consistency, making it ideal for producing intricate components and prototypes. CNC plastic machining is versatile, accommodating a range of plastics like acrylic, polycarbonate, and nylon. It’s commonly used in automotive, aerospace, and electronics industries to create custom parts and detailed features, offering efficient production and high-quality finishes.

—SY PLASTIC ENGINEERING —

BLOG POSTS

— SY PLASTIC ENGINEERING SERVICES —

Huzhou Shengyi New Material Technology Co., Ltd. is a leading company in the field of engineering plastic products.