CNC for PTFE Products

September 30, 2024

How PTFE Works?

September 30, 2024Introduction to PTFE

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer known for its remarkable chemical resistance, low friction properties, and high-temperature stability. Commonly recognized by the brand name Teflon, PTFE has become a staple in various industries due to its unique characteristics.

Properties of PTFE

PTFE exhibits several key properties that make it an exceptional material:

- Chemical Resistance: PTFE is virtually inert, allowing it to withstand exposure to a wide range of chemicals, including acids and bases, without degrading.

- High-Temperature Tolerance: It can maintain its structural integrity and performance at temperatures up to 260°C (500°F).

- Low Friction Coefficient: PTFE has one of the lowest coefficients of friction among solid materials, making it ideal for applications where sliding contact is involved.

- Non-stick Surface: Its non-adhesive properties prevent substances from bonding to it, making it easy to clean and maintain.

Common Applications of PTFE

PTFE products are used across numerous industries, including:

- Aerospace: For seals, gaskets, and insulation due to its thermal stability and chemical resistance.

- Food Processing: Non-stick coatings for cookware and food processing equipment, ensuring safety and ease of cleaning.

- Electrical: Insulation for wires and cables, as PTFE’s dielectric properties enhance performance in high-frequency applications.

- Medical: Implants and surgical devices benefit from PTFE’s biocompatibility and resistance to bodily fluids.

Manufacturing PTFE Products

PTFE products can be produced through various methods, including:

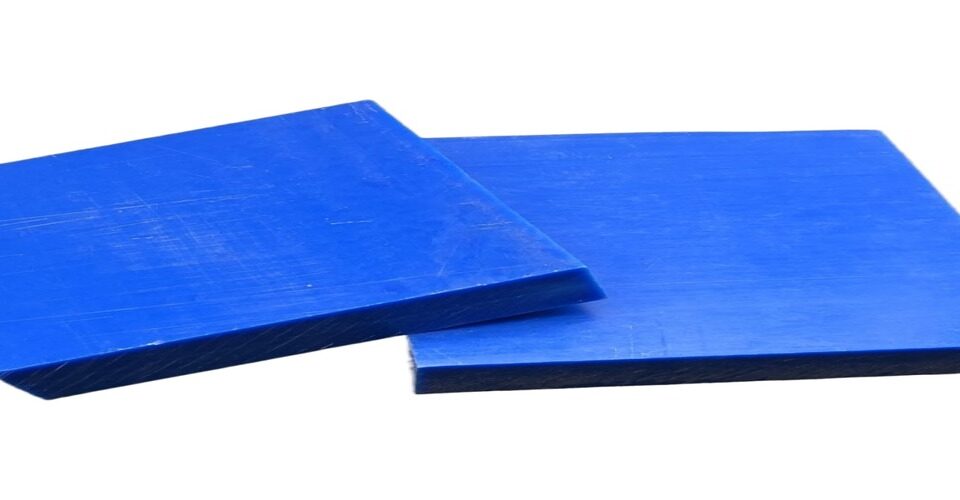

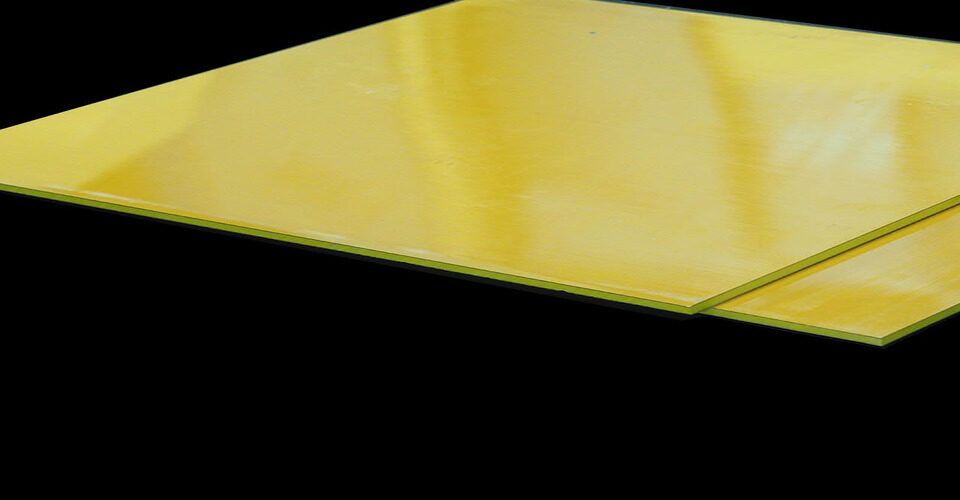

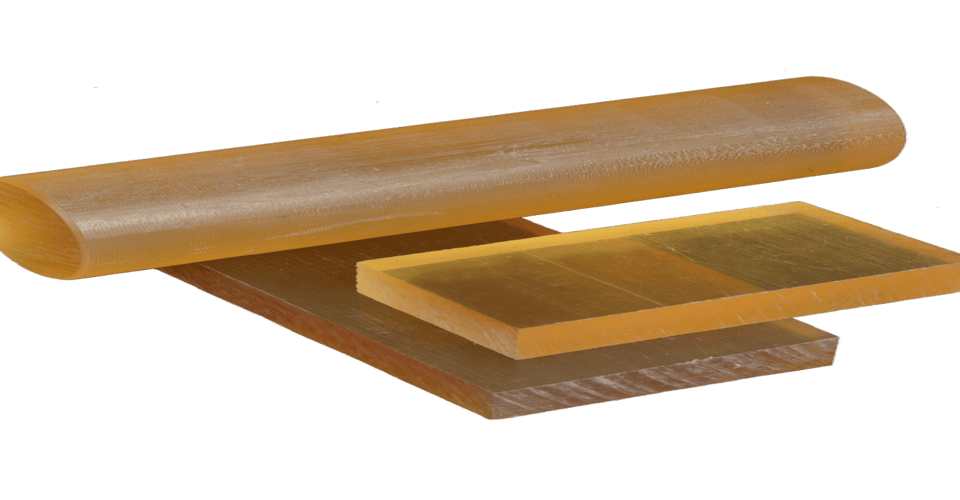

- Extrusion: PTFE is heated and forced through a die to create rods, tubes, or sheets.

- Molding: Powders are compressed and heated to form specific shapes, allowing for intricate designs.

- CNC Machining: Advanced CNC machining techniques enable precise shaping and finishing of PTFE components.

Conclusion

PTFE is a versatile and highly functional material with applications that span multiple industries. Its unique properties, including chemical resistance and low friction, make it an ideal choice for various demanding applications, ensuring reliability and performance in critical environments.