Plastic is Used in CNC?

October 9, 2024

Difference B/W PTFE and PPS

October 10, 2024PPS, or Polyphenylene Sulfide, is a high-performance thermoplastic known for its exceptional thermal and chemical resistance. This material is often used in demanding applications where standard plastics would fail.

Properties of PPS Plastic

PPS boasts a unique combination of properties that make it ideal for various industrial applications. It has a high melting point, typically around 280°C (536°F), allowing it to maintain structural integrity in extreme temperatures. Its excellent chemical resistance enables it to withstand aggressive solvents, acids, and bases, making it suitable for environments where other materials would degrade.

Applications of PPS Plastic

Due to its remarkable properties, PPS is commonly used in the automotive, electrical, and aerospace industries. It is often employed in manufacturing components like connectors, housings, and insulators that require durability and reliability. In the automotive sector, PPS is used for fuel system components and under-the-hood applications, where exposure to high temperatures and chemicals is common.

Machinability and Processing

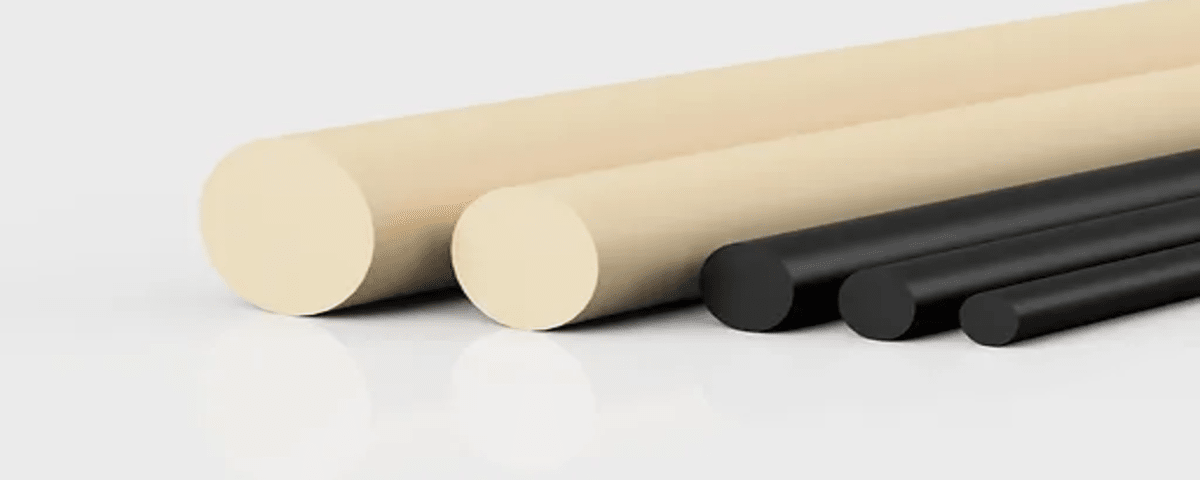

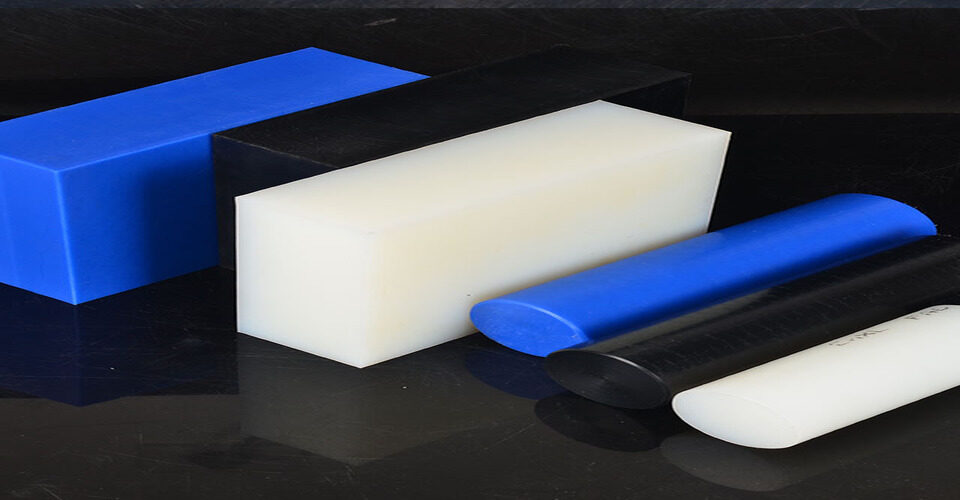

PPS can be machined using standard techniques, although care must be taken due to its toughness. It can be processed through methods such as injection molding and extrusion. Specialized tools may be required to achieve precise tolerances and finishes.

Conclusion

In summary, PPS plastic is a versatile, high-performance material suited for applications that demand resilience to heat and chemicals. Its unique properties make it a preferred choice in industries where reliability and durability are paramount.