What Material is CNC?

October 16, 2024

LDPE or HDPE is better?

October 16, 2024Yes, PPS, or polyphenylene sulfide, is indeed a polymer. It belongs to the family of engineering thermoplastics and is known for its remarkable thermal and chemical resistance.

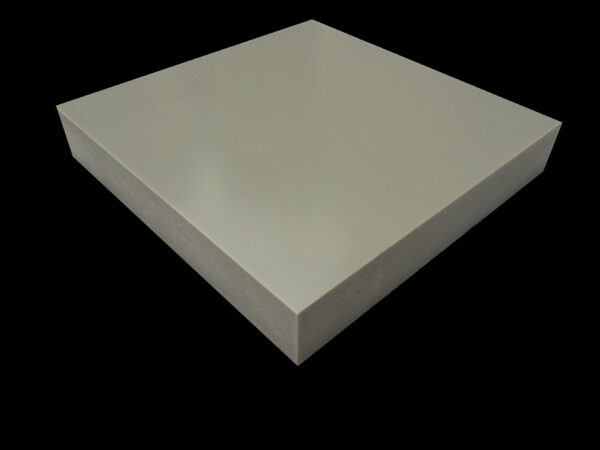

Structure of PPS

PPS is a semi-crystalline polymer that consists of repeating units of phenylene and sulfide groups. This unique structure contributes to its high stability and performance under extreme conditions. The polymer’s molecular arrangement allows it to maintain its strength at elevated temperatures, making it suitable for various demanding applications.

Properties of PPS

PPS exhibits a range of desirable properties that make it a preferred choice in many industries. It has a high melting point, around 280°C (536°F), and excellent dimensional stability. Furthermore, PPS is resistant to a wide array of chemicals, including acids, bases, and solvents, which enhances its durability in harsh environments.

Applications of PPS

Due to its exceptional properties, PPS is widely used in industries such as automotive, aerospace, and electronics. It is commonly found in applications like connectors, insulators, and components requiring high-temperature resistance. Additionally, PPS is utilized in the manufacture of filtration membranes and other specialized products.

Conclusion

In summary, PPS is a versatile polymer known for its excellent thermal and chemical resistance. Its unique structure and properties make it suitable for a wide range of applications, establishing it as a vital material in various high-performance sectors.