PI Plastic vs. PEEK

October 16, 2024

PCTFE Chemical Compatibility

October 17, 2024Introduction

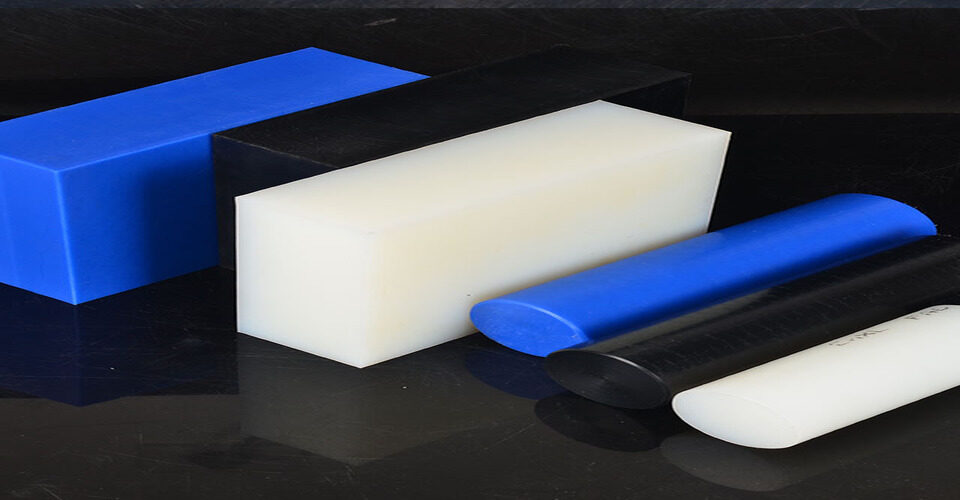

Polymers are essential in various industries, and among them, PCTFE (Polychlorotrifluoroethylene) and PTFE (Polytetrafluoroethylene) stand out due to their unique properties. Understanding the differences between these two materials is crucial for selecting the right one for specific applications.

Chemical Structure

PCTFE is derived from chlorotrifluoroethylene, while PTFE is made from tetrafluoroethylene. This difference in chemical structure influences their thermal stability, chemical resistance, and mechanical properties.

Properties

PCTFE

- Chemical Resistance: Excellent resistance to solvents and chemicals.

- Thermal Stability: Can withstand temperatures up to 200°C (392°F).

- Mechanical Strength: Good tensile strength and rigidity, making it suitable for high-performance applications.

PTFE

- Chemical Resistance: Exceptional resistance to a broader range of chemicals.

- Thermal Stability: Operates efficiently up to 260°C (500°F).

- Mechanical Strength: Lower tensile strength compared to PCTFE but superior flexibility and non-stick properties.

Applications

PCTFE

Commonly used in cryogenic applications, seals, and gaskets due to its durability and low permeability to gases.

PTFE

Widely used in cookware, seals, and insulation, particularly where a non-stick surface is required.

Conclusion

In summary, the choice between PCTFE and PTFE depends on the specific requirements of the application. While PCTFE offers greater rigidity and lower gas permeability, PTFE provides better thermal stability and chemical resistance. Understanding these differences can help in making informed decisions in material selection.