What Does PEI Mean Material?

October 18, 2024

PI Plastic in China

October 18, 2024EPI and PEI are two distinct materials, though they share some similarities in their applications and properties. Understanding the differences between them is crucial for selecting the appropriate material for specific needs.

Definitions

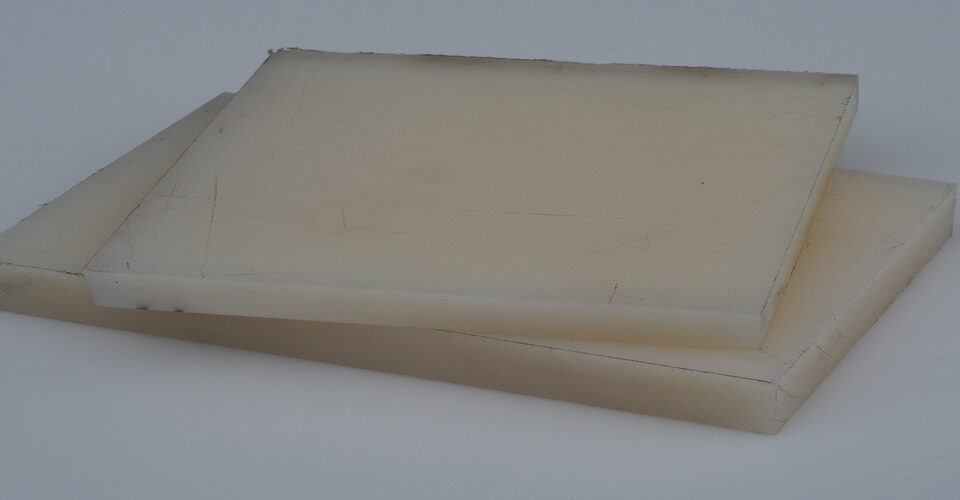

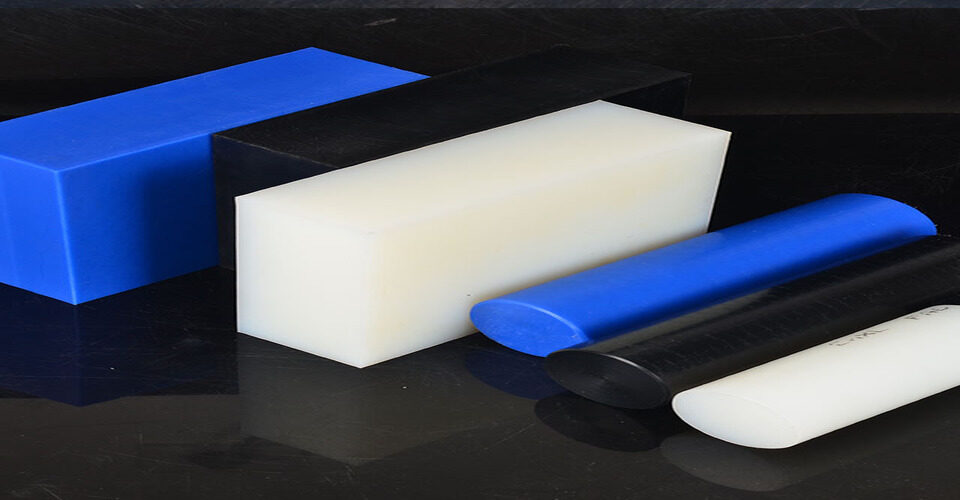

EPI, or Epoxy Phenolic Intermediate, is a type of resin primarily used in coatings and adhesives. It combines the properties of epoxy and phenolic resins, resulting in a material that is both strong and resistant to heat and chemicals. On the other hand, PEI, or Polyetherimide, is a high-performance thermoplastic known for its mechanical strength, thermal stability, and resistance to various chemicals.

Properties

While both materials exhibit high thermal resistance, PEI generally has a higher glass transition temperature, making it suitable for applications involving extreme heat. EPI, although heat-resistant, is typically used in applications where flexibility and adhesion are paramount. PEI’s superior mechanical properties make it ideal for structural components, while EPI is more commonly used in coatings and bonding applications.

Applications

PEI is often found in aerospace, automotive, and medical industries, where durability and performance are essential. EPI, conversely, is more prevalent in manufacturing paints, coatings, and sealants, where adhesion and chemical resistance are critical.

Conclusion

In conclusion, EPI and PEI serve different purposes and possess unique characteristics. While they may be used in similar fields, their distinct properties make them suitable for different applications. Understanding these differences is key to making informed material choices.