Key Applications of PMMA

October 21, 2024

Who Makes PCTFE?

October 21, 20241. Introduction to PPS

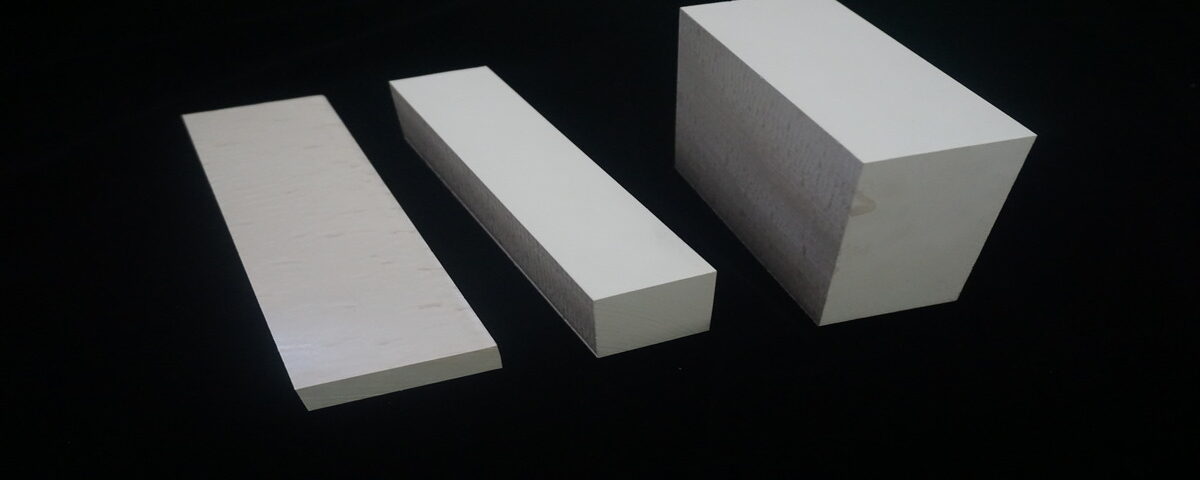

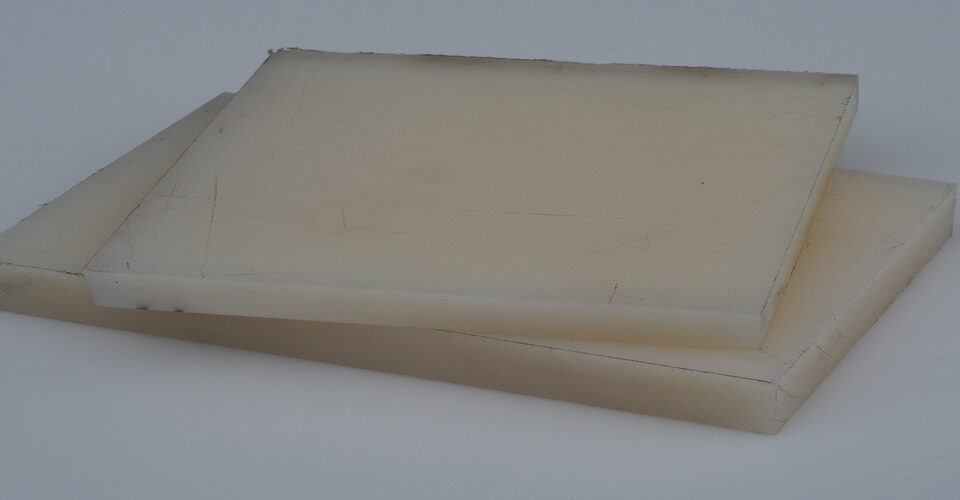

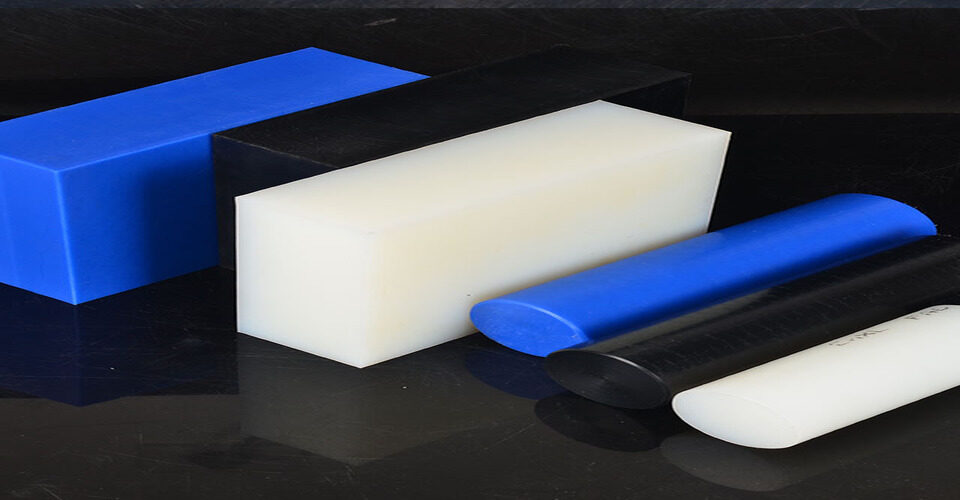

PPS (Polyphenylene Sulfide) is a high-performance thermoplastic known for its exceptional chemical resistance and thermal stability. PPS plastic sheets are widely used in various industries due to their unique properties.

2. Chemical Resistance

One of the standout features of PPS plastic sheets is their outstanding chemical resistance. They can withstand harsh chemicals, making them ideal for use in environments where exposure to acids, bases, and solvents is common.

3. High-Temperature Applications

PPS can maintain its mechanical properties at elevated temperatures, making it suitable for applications in high-temperature environments. This characteristic is particularly beneficial in the automotive and aerospace industries.

4. Electrical Insulation

PPS plastic sheets are excellent electrical insulators, making them a preferred choice for electronic applications. Their dielectric properties help protect sensitive components from electrical interference.

5. Mechanical Strength

PPS exhibits impressive mechanical strength and rigidity, allowing it to withstand stress and wear. This makes it an ideal material for components that require durability and longevity.

6. Use in Automotive Parts

In the automotive sector, PPS plastic sheets are used for manufacturing components such as connectors, housings, and insulation parts. Their resilience under extreme conditions contributes to vehicle reliability.

7. Applications in Aerospace

The aerospace industry utilizes PPS for various components due to its lightweight nature and high-performance characteristics. It helps improve fuel efficiency while ensuring structural integrity.

8. Summary

Overall, PPS plastic sheets are versatile materials that offer a combination of chemical resistance, thermal stability, and mechanical strength, making them essential in multiple industrial applications.