Can PTFE be molded?

October 29, 2024

PTFE bar ram extrusion machine

October 30, 2024Polytetrafluoroethylene (PTFE) is a versatile polymer known for its exceptional chemical resistance and high-temperature stability. One common question regarding PTFE is whether it can be extruded.

Understanding PTFE Extrusion

Extrusion is a manufacturing process used to create objects of a fixed cross-sectional profile by pushing material through a die. While many thermoplastics can be easily extruded, PTFE presents unique challenges due to its specific properties.

The Nature of PTFE

PTFE is classified as a fluoropolymer and is notable for its high melting point and low friction characteristics. Unlike typical thermoplastics, PTFE does not melt in the same way; instead, it softens when heated. This behavior complicates the extrusion process, as traditional extrusion methods rely on melting the material for shaping.

Methods for Extruding PTFE

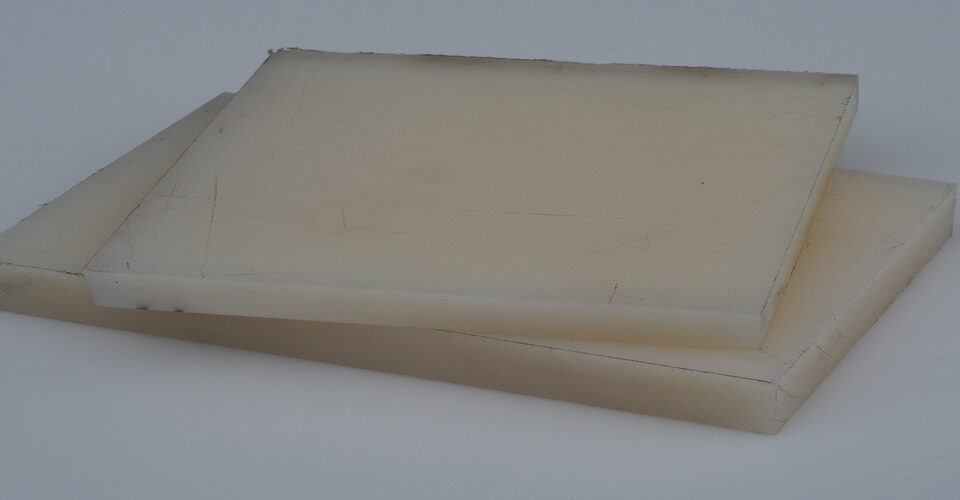

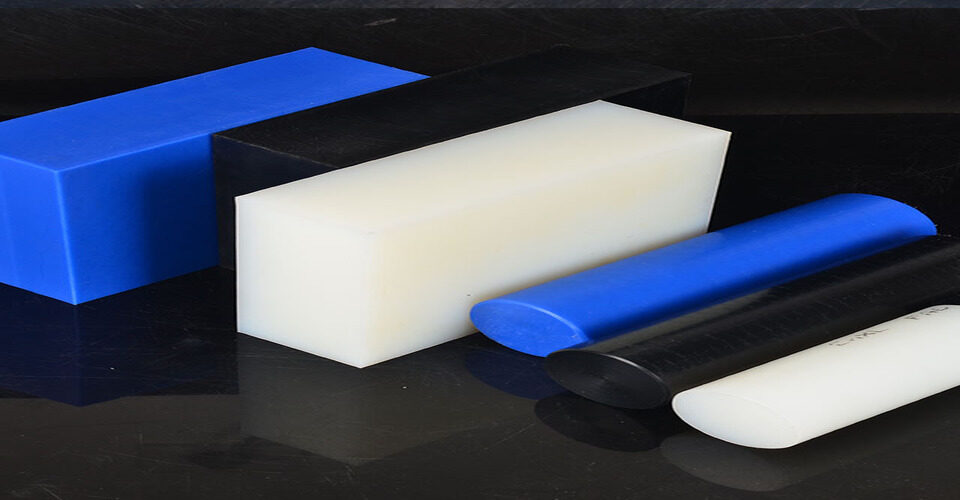

Although PTFE cannot be extruded in the conventional sense, specialized techniques can achieve similar outcomes. One approach involves using a paste extrusion method, where PTFE is mixed with a lubricant to form a paste. This paste can be forced through a die to create various shapes.

Applications of Extruded PTFE

Extruded PTFE products are widely used in industries that require high-performance materials, such as chemical processing, aerospace, and electrical insulation. The ability to create complex shapes makes PTFE useful for seals, gaskets, and tubing.

Conclusion

In summary, while PTFE cannot be extruded using standard methods, specialized techniques enable the production of PTFE components, making it a valuable material in various applications.