Can PTFE be thermoformed?

October 29, 2024

Can PTFE be extruded?

October 29, 2024Polytetrafluoroethylene (PTFE) is a high-performance polymer renowned for its unique properties, including excellent chemical resistance and thermal stability. A common question arises: can PTFE be molded?

Understanding PTFE Molding

Molding is a manufacturing process that involves shaping material into specific forms using a mold. While many thermoplastics can be easily molded, PTFE behaves differently, presenting specific challenges.

The Nature of PTFE

PTFE is a fluoropolymer that does not melt like traditional plastics. Instead, it softens at elevated temperatures, making conventional injection molding impractical. This characteristic necessitates alternative methods for molding PTFE.

Methods for Molding PTFE

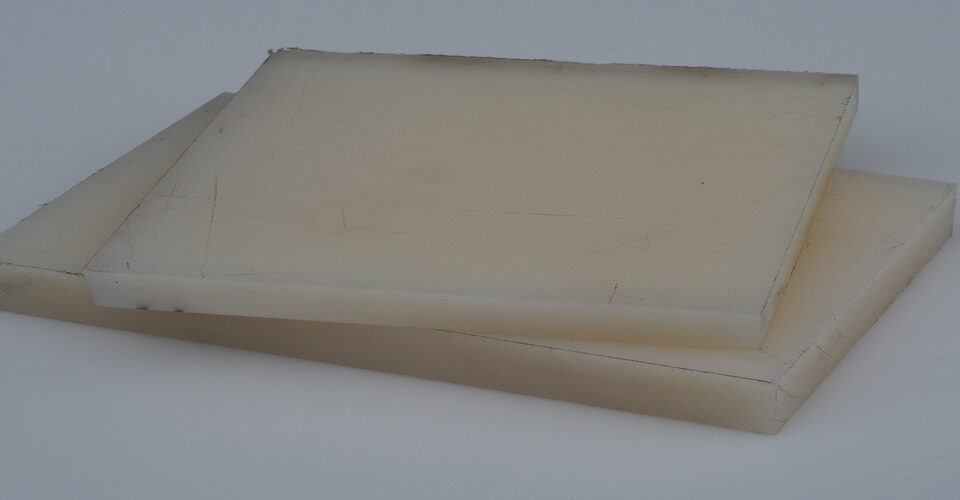

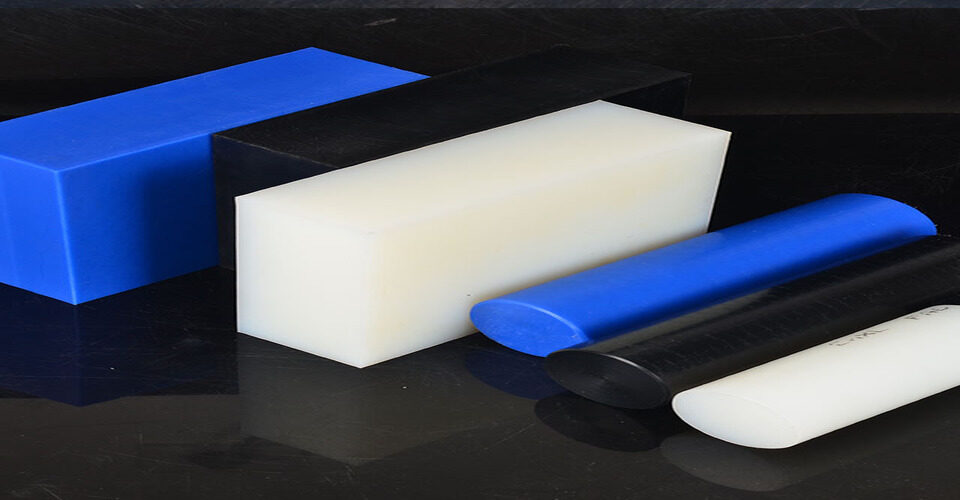

One popular technique for molding PTFE is compression molding. In this method, powdered PTFE is placed in a mold and heated under pressure. The heat causes the polymer to soften and fill the mold, creating the desired shape. Another technique is ram extrusion, where PTFE powder is forced through a die to form long, continuous shapes.

Applications of Molded PTFE

Molded PTFE is widely used in various industries, including chemical processing, pharmaceuticals, and electronics. Its excellent resistance to chemicals and temperatures makes it ideal for applications such as seals, gaskets, and insulating components.

Conclusion

In summary, while PTFE cannot be molded using standard injection molding methods, alternative techniques like compression molding and ram extrusion enable the effective shaping of this versatile polymer, making it invaluable in numerous applications.