Automatic Ram Extrusion Machine for PTFE Rod

October 31, 2024

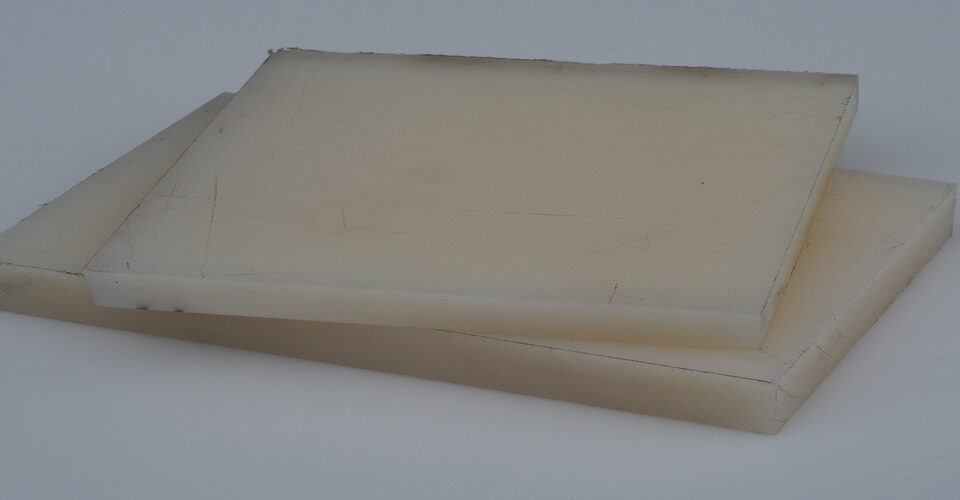

PTFE sheet skived machine for PTFE molding

October 31, 2024Introduction

PTFE tube, made from polytetrafluoroethylene, is a versatile and widely used material in various industries. Known for its excellent chemical resistance and low friction properties, PTFE tubing serves a range of applications, from industrial processes to consumer goods.

Properties

Chemical Resistance

One of the standout features of PTFE tubes is their exceptional resistance to a wide array of chemicals. They can withstand harsh environments without degrading, making them ideal for industries such as pharmaceuticals and chemicals.

Temperature Tolerance

PTFE can operate effectively across a wide temperature range, typically from -200°C to +260°C. This thermal stability allows it to maintain its properties under extreme conditions.

Applications

Industrial Uses

PTFE tubes are commonly used in industries such as food processing, automotive, and aerospace. They are often employed in applications requiring non-stick surfaces, such as conveyor belts and seals.

Medical Applications

In the medical field, PTFE tubing is used for catheters and other medical devices due to its biocompatibility and low friction, which helps reduce the risk of irritation.

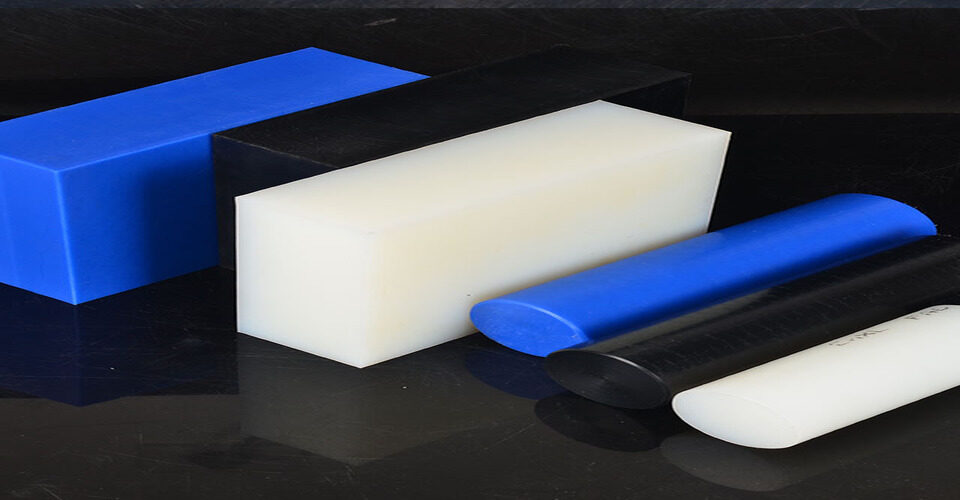

Manufacturing Process

PTFE tubes are produced through processes like extrusion and sintering, ensuring consistent quality and performance. The manufacturing techniques allow for various sizes and thicknesses to meet specific requirements.

Conclusion

PTFE tubes are a vital component in many applications due to their unique properties. Their durability, chemical resistance, and versatility make them an excellent choice for industries that demand reliable performance in challenging environments.