High-End Engineering Polyvinylidene Fluoride

October 31, 2024

What is Bakelite Used For?

November 1, 2024Bakelite, invented in the early 20th century, is one of the first synthetic plastics and is known for its distinctive properties. But how strong is Bakelite compared to modern plastics?

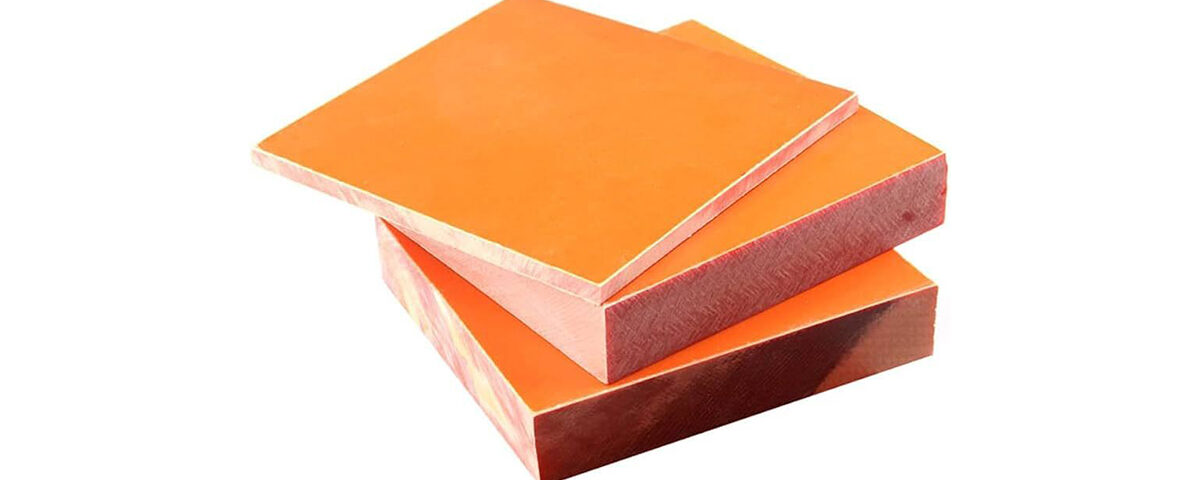

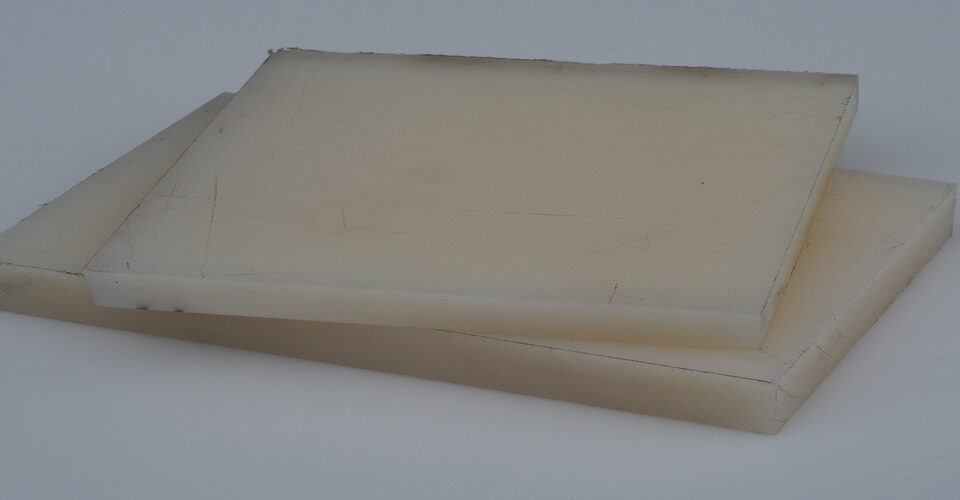

Composition and Structure

Bakelite is a thermosetting phenolic resin created from phenol and formaldehyde. Once cured, it forms a hard, durable material that does not melt upon heating. This structural integrity contributes significantly to its strength.

Impact Resistance

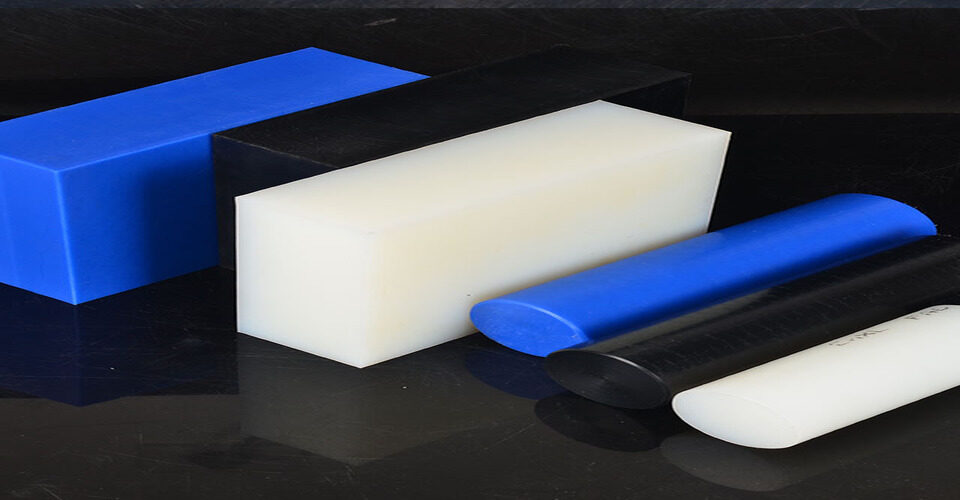

While Bakelite is quite rigid and has good compressive strength, it is less impact-resistant compared to some modern plastics like ABS or polycarbonate. It can crack or shatter under high impact, making it less suitable for applications requiring flexibility or high resilience.

Chemical Resistance

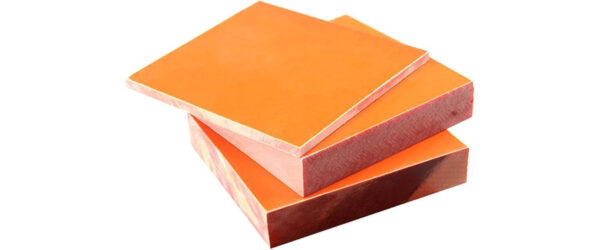

Bakelite exhibits excellent resistance to heat, chemicals, and electrical currents, which enhances its durability in various environments. This makes it a popular choice for electrical insulators and kitchenware, where exposure to heat and chemicals is common.

Applications

Due to its strength and resistance properties, Bakelite has been widely used in the manufacturing of items like electrical switches, radio casings, and kitchen utensils. Its ability to maintain shape and resist wear over time makes it a reliable material.

Limitations

Despite its strength, Bakelite is relatively brittle and can be prone to chipping or breaking under certain conditions. Modern plastics often outperform Bakelite in terms of flexibility and impact resistance.

Conclusion

In summary, Bakelite is a strong plastic for many applications, especially where heat and chemical resistance are required. However, its brittleness limits its performance in situations where flexibility and impact resistance are crucial.