Is POM Plastic Strong?

November 5, 2024

What is the best plastic to CNC?

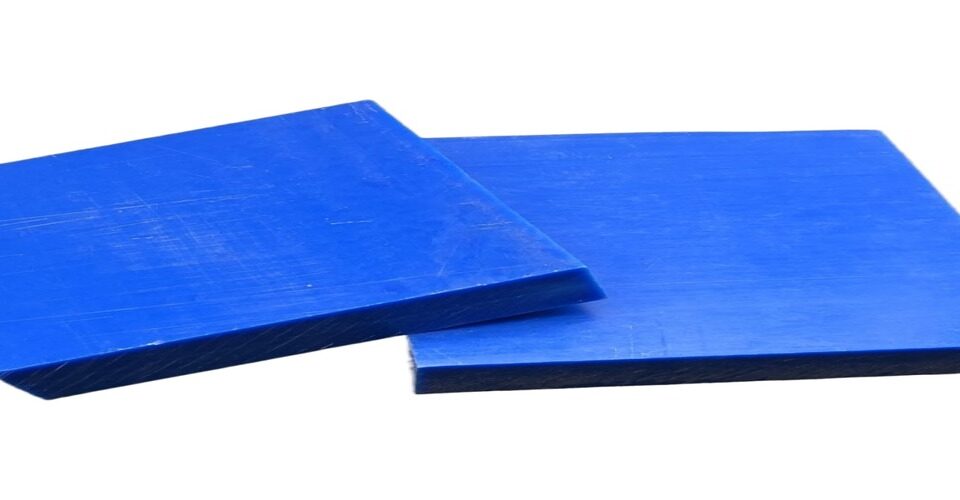

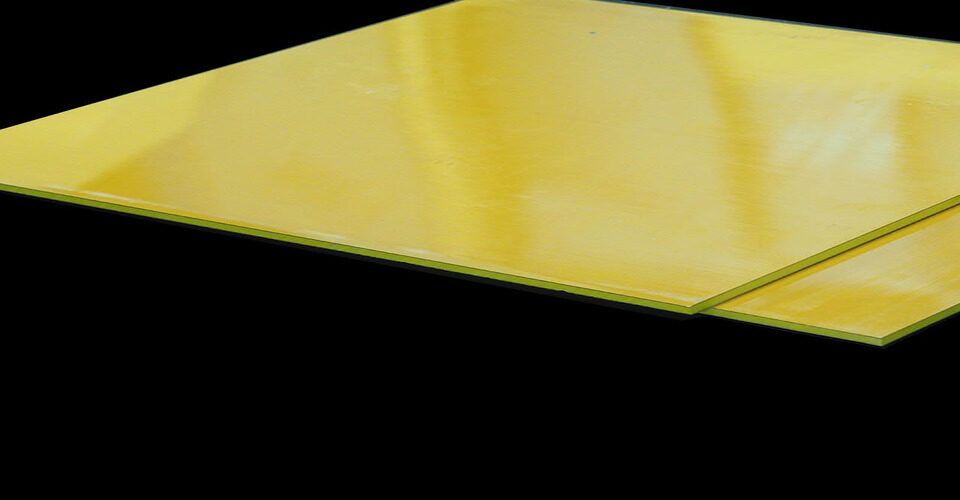

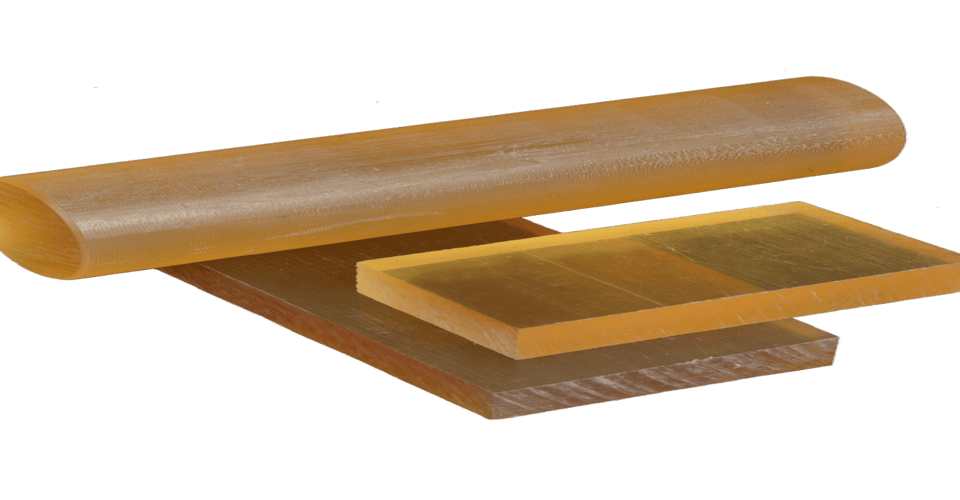

November 5, 2024UPE (Ultra-High Molecular Weight Polyethylene) is a type of plastic known for its exceptional strength, wear resistance, and low friction properties. It is a highly durable material that has found widespread use in demanding applications across various industries, including aerospace, automotive, medical, and manufacturing.

Characteristics of UPE Plastic

UPE plastic stands out due to its ultra-high molecular weight, which contributes to its remarkable strength and impact resistance. It has a very high resistance to abrasion and wear, making it ideal for situations where parts are subject to continuous friction or movement. Additionally, UPE has excellent chemical resistance, making it suitable for use in harsh environments, including exposure to acids, alkalis, and other corrosive substances.

Applications of UPE Plastic

UPE plastic is commonly used in the production of conveyor belts, bearings, bushings, and wear plates. Its low coefficient of friction makes it a top choice for applications requiring smooth and quiet operation. Additionally, it’s used in the manufacturing of components for industries such as food processing, mining, and pharmaceuticals, where high durability and cleanliness are essential.

Benefits of UPE Plastic

The key benefits of UPE plastic include its outstanding abrasion resistance, low friction coefficient, and high impact strength. UPE also boasts excellent performance in low temperatures and is self-lubricating, reducing the need for external lubrication. It’s also a lightweight material, which adds to its appeal in industries where weight reduction is important.

Conclusion

UPE plastic is a versatile and high-performance material suitable for a wide range of industrial and commercial applications. Its combination of durability, chemical resistance, and low friction properties makes it an excellent choice for demanding environments.