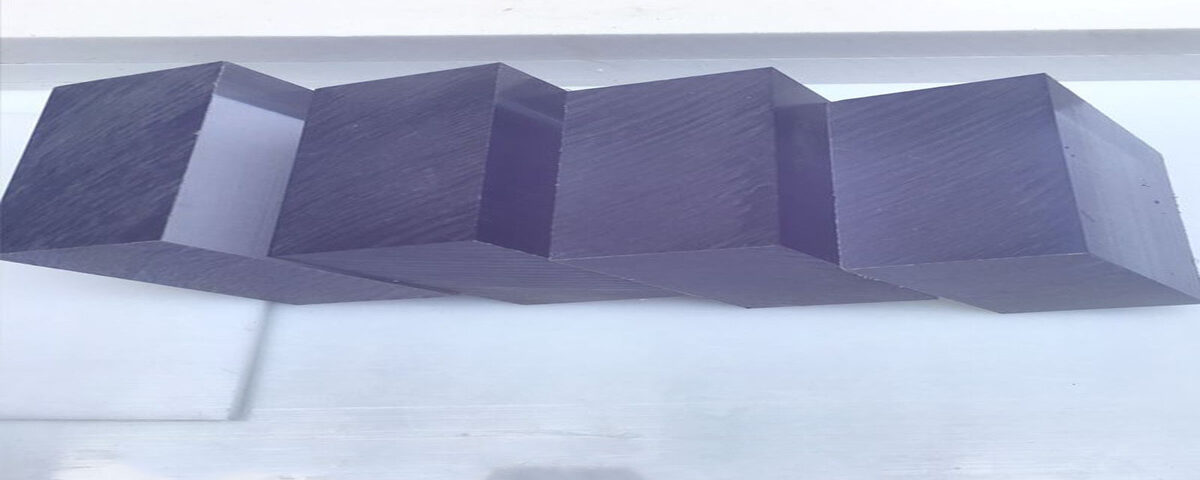

UHMW Polyethylene Plastic Sheet

November 4, 2024

Is POM Plastic Better Than PP?

November 5, 2024When choosing between PC (Polycarbonate) and PET (Polyethylene Terephthalate), it’s important to understand their unique properties to determine which one is better suited for your specific needs. Both are versatile plastics commonly used in a variety of applications, but they differ in key areas such as strength, clarity, and resistance.

Strength and Durability

PC plastic is known for its exceptional impact resistance, making it one of the toughest plastics available. It can withstand high levels of stress and is less likely to crack or shatter under pressure, which is why it’s often used in safety equipment, eyewear lenses, and protective covers. PET, while also strong, is more prone to cracking under impact compared to PC. As a result, PC is generally the better choice for applications that require superior durability and toughness.

Clarity and Optical Properties

PC plastic is highly transparent, making it an ideal material for applications that require clear, optically pure plastics, such as eyewear lenses, automotive light covers, and optical lenses. PET is also transparent but tends to have a lower optical clarity and less resistance to scratching, making it less suitable for high-clarity applications.

Chemical and Heat Resistance

PC has better heat resistance than PET, withstanding temperatures up to 135°C (275°F) compared to PET’s 70°C (158°F). However, PET has superior resistance to certain chemicals, including acids and bases, making it ideal for packaging food and beverages.

Cost-Effectiveness

PET is generally less expensive than PC, which makes it more suitable for mass-production applications like bottles, containers, and packaging. PC, on the other hand, tends to be pricier due to its enhanced performance characteristics.

Conclusion

PC plastic is better than PET in terms of impact resistance, heat tolerance, and optical clarity, making it ideal for high-performance applications. However, PET offers cost advantages and superior chemical resistance, making it a better choice for packaging and general consumer products. The choice depends on your specific requirements, including durability, cost, and performance.