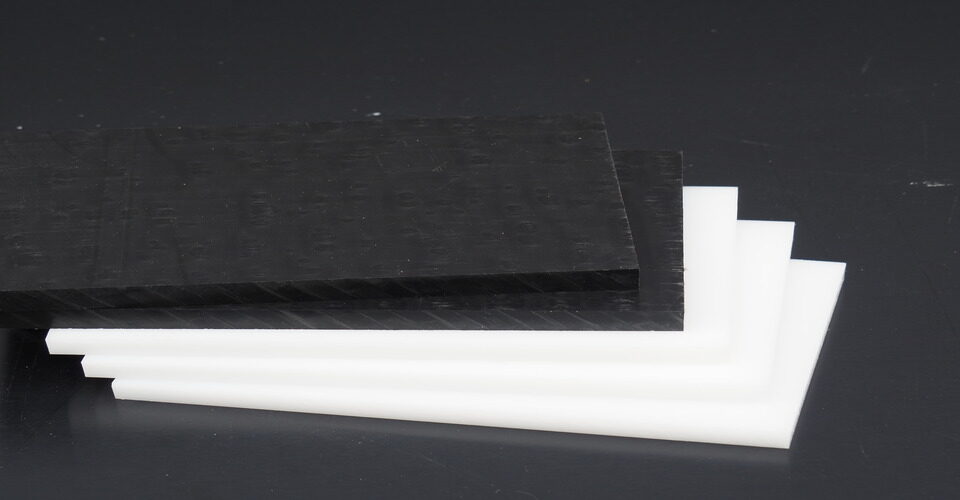

PCTFE Sheet Shipment from China to Mexico

November 6, 2024

What is PU Plastic?

November 11, 2024When comparing Polyurethane (PU) and rubber, it’s important to understand the differences in their properties and applications. Both materials have unique characteristics, making them suitable for a wide range of industries. However, depending on the use case, one might be better than the other.

Durability and Strength

PU is generally more durable and resistant to abrasion compared to rubber. It can withstand higher levels of wear and tear, making it ideal for applications like wheels, rollers, and coatings. Rubber, while elastic and flexible, can degrade faster when exposed to harsh environmental conditions such as UV light, extreme temperatures, or chemicals.

Flexibility and Comfort

Rubber is known for its flexibility and comfort, which is why it’s commonly used in footwear, seals, and gaskets. PU, while also flexible, tends to be stiffer than rubber, but this can be advantageous in applications where rigidity and shape retention are important.

Cost-Effectiveness

Rubber is generally more affordable than PU, particularly in large-scale production. However, PU’s superior durability and longer lifespan can make it more cost-effective in the long run, especially in products subject to heavy wear.

Environmental Considerations

Rubber, especially natural rubber, is a renewable resource. PU, however, is often derived from petrochemicals, although bio-based alternatives are becoming more common. Environmental impact depends on the type of material used and the recycling options available.

Conclusion

Ultimately, whether PU is better than rubber depends on the specific requirements of the application. For high durability and wear resistance, PU may be the superior choice. However, for flexibility and lower cost, rubber could be more suitable.