Is PU Better Than Rubber?

November 11, 2024

What is PP used for plastic?

November 11, 2024PU plastic, or polyurethane plastic, is a versatile synthetic material formed by polymerizing urethane compounds. It is a type of polymer that is widely used across various industries due to its flexibility, durability, and range of customizable properties. PU plastics are often found in products ranging from foams and coatings to elastomers and adhesives.

Composition of PU Plastic

Polyurethane plastic is created by combining diisocyanates (usually methylene diphenyl diisocyanate, MDI) with polyols. The chemical reaction between these two substances forms the polyurethane polymer. By adjusting the ratio and type of diisocyanates and polyols used, manufacturers can control the final material’s hardness, flexibility, and other characteristics.

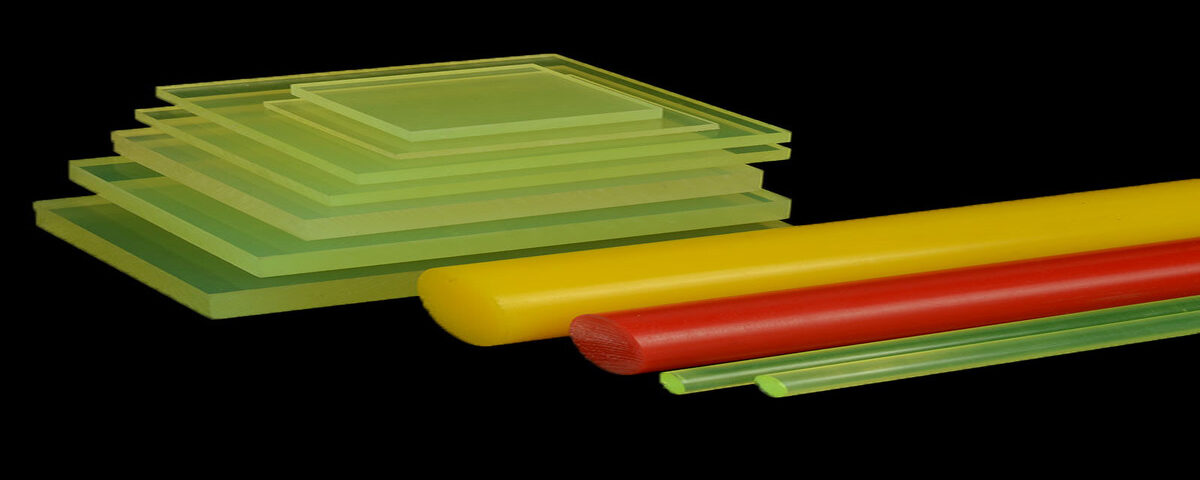

Types of PU Plastic

There are two primary forms of polyurethane plastics: rigid and flexible. Rigid polyurethane is used in applications such as insulation panels and rigid foams, while flexible PU is used for products like foams in furniture, car seats, and mattresses. Additionally, there are thermoplastic and thermoset variations of PU, each with different processing methods and properties.

Applications of PU Plastic

PU plastic is incredibly versatile and is used in a wide array of products. Some of the most common applications include foams for furniture and bedding, coatings for surfaces like floors and automotive parts, elastomers in tires, seals, and gaskets, and adhesives in construction and manufacturing.

Advantages of PU Plastic

PU plastic is known for its high durability, resistance to abrasion, and ability to withstand harsh environmental conditions. It is also highly customizable, allowing for products with varying degrees of hardness, flexibility, and resilience.

Conclusion

PU plastic is a highly versatile and durable material with applications in numerous industries. Its unique properties make it ideal for a wide range of uses, from soft, flexible foams to tough, rigid components.