What is Virgin UHMW?

November 28, 2024

What are the properties of ABS plastic?

November 28, 2024PVC (Polyvinyl Chloride) and ABS (Acrylonitrile Butadiene Styrene) are both popular types of plastic used across various industries. Though they share similarities, they have distinct properties that make each suitable for different applications.

What is PVC Plastic?

PVC is a synthetic plastic polymer made from the polymerization of vinyl chloride monomer. It is one of the most widely produced plastics globally and is often used in construction, healthcare, and electrical applications. PVC is available in two main forms: rigid and flexible. Rigid PVC is commonly used for pipes, doors, and windows, while flexible PVC is used in flooring, wiring, and medical tubing.

What is ABS Plastic?

ABS is a thermoplastic made from a combination of acrylonitrile, butadiene, and styrene. It is known for its toughness, strength, and impact resistance. ABS is commonly used in consumer products, automotive parts, electronics, and toys due to its excellent durability and aesthetic appeal. It can be easily molded and has a smooth, glossy finish.

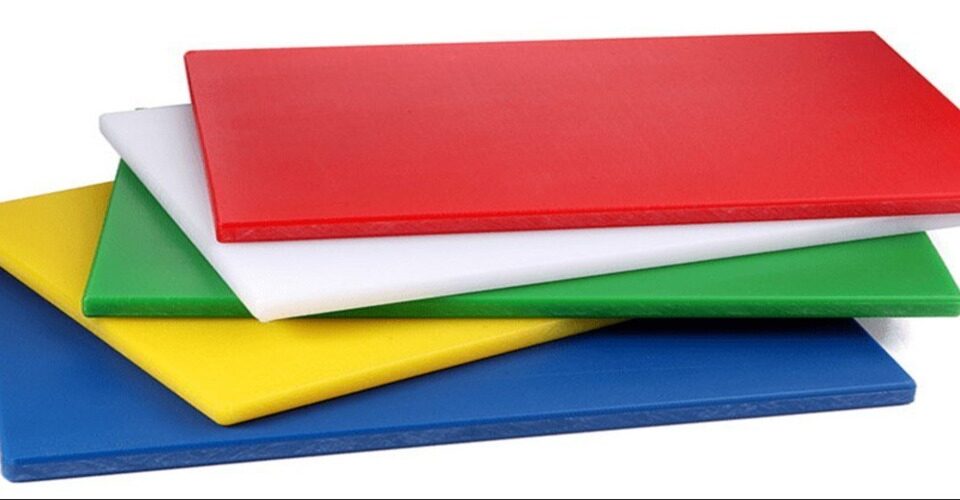

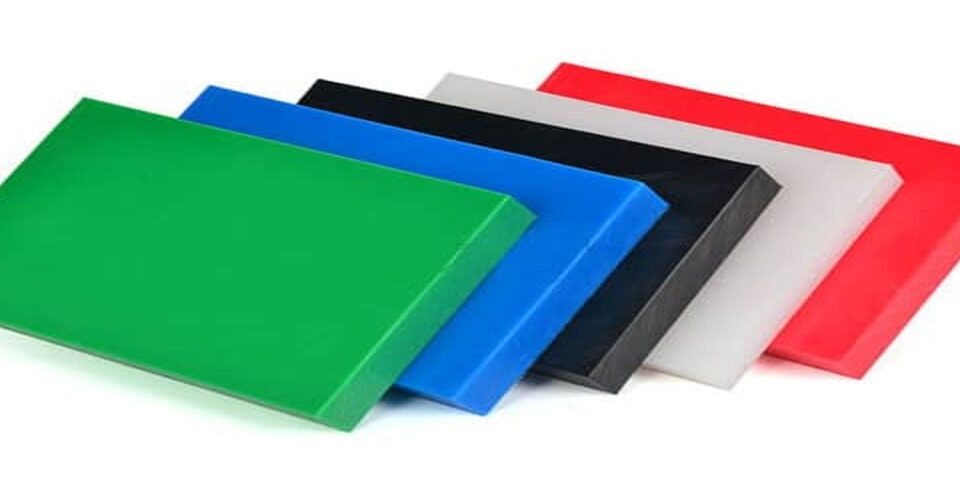

Differences Between PVC and ABS

While both are thermoplastics, PVC is known for its chemical resistance and is often used in plumbing and construction. ABS, on the other hand, is preferred in applications requiring higher impact resistance and strength, such as automotive parts and high-performance consumer products. PVC is also more flexible than ABS, which is rigid and tougher.

Conclusion

PVC and ABS are distinct materials, each with unique characteristics. Choosing between them depends on the specific requirements of strength, flexibility, and application in various industries.