What Are the Uses of PSU Plastic?

December 24, 2024

What Is PFA in Quality?

December 24, 2024High Mechanical Strength

Yes, PPS (Polyphenylene Sulfide) plastic is exceptionally strong. It is known for its outstanding mechanical properties, making it ideal for demanding applications. Its rigidity and structural integrity remain consistent even under stress, ensuring reliable performance in critical environments.

Temperature Resistance

PPS plastic exhibits remarkable strength across a wide temperature range. It can maintain its structural stability at temperatures as high as 200–240°C, which makes it suitable for high-heat applications like automotive and industrial machinery components.

Chemical Resistance

One of the reasons PPS is considered strong is its resistance to harsh chemicals. It does not degrade when exposed to acids, bases, solvents, or fuels, giving it an edge over many other plastics in environments where chemical exposure is a concern.

Dimensional Stability

PPS plastic offers excellent dimensional stability due to its low moisture absorption and thermal expansion. This ensures that components made from PPS maintain their shape and strength, even in environments with fluctuating humidity or temperature.

Abrasion Resistance

PPS is highly resistant to wear and abrasion. This property, combined with its strength, makes it an ideal material for gears, bushings, and other parts that experience friction during operation.

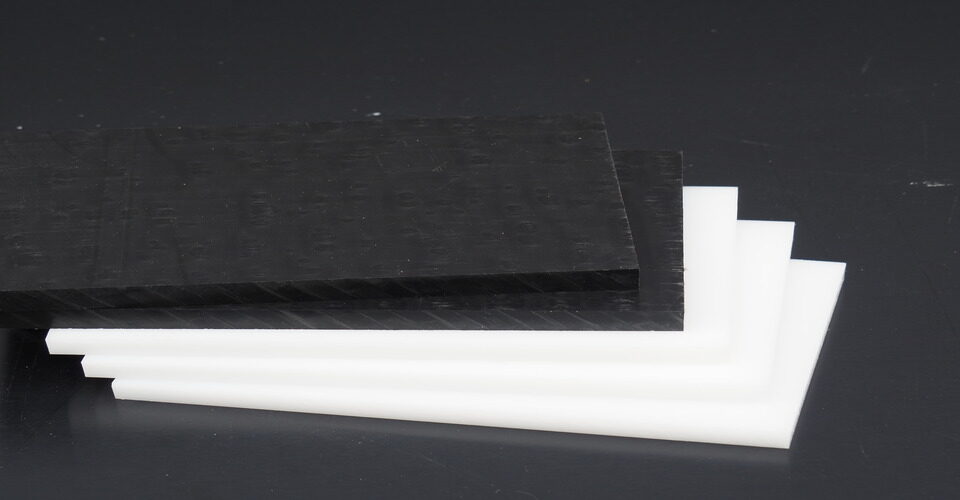

Reinforced Grades

The strength of PPS plastic can be further enhanced by incorporating fillers like glass fibers or carbon fibers. These reinforced grades significantly boost its mechanical properties, making PPS suitable for heavy-duty applications in automotive, aerospace, and industrial sectors.