What materials are used in ABS?

January 10, 2025

What material is used for machining PEEK plastic?

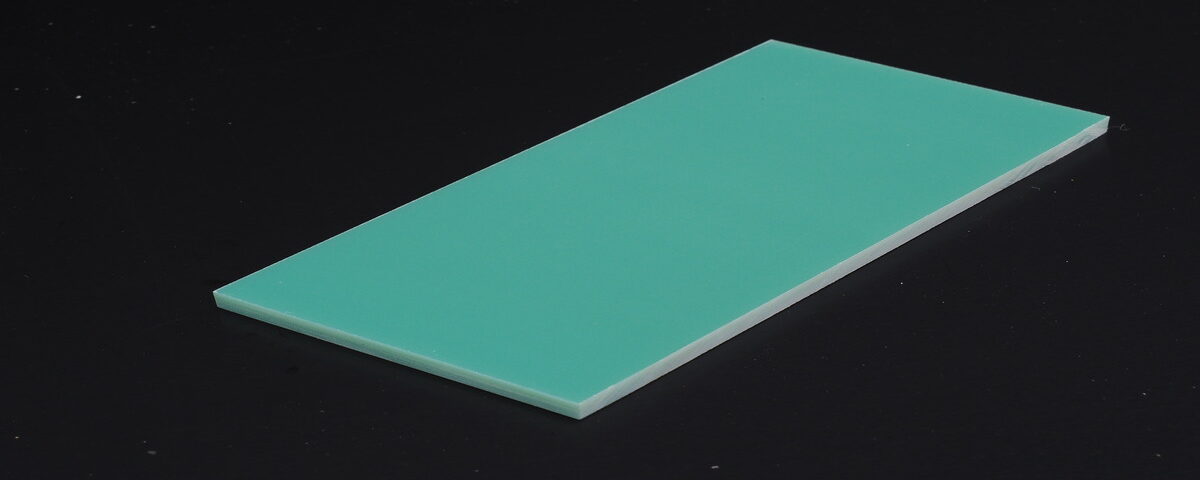

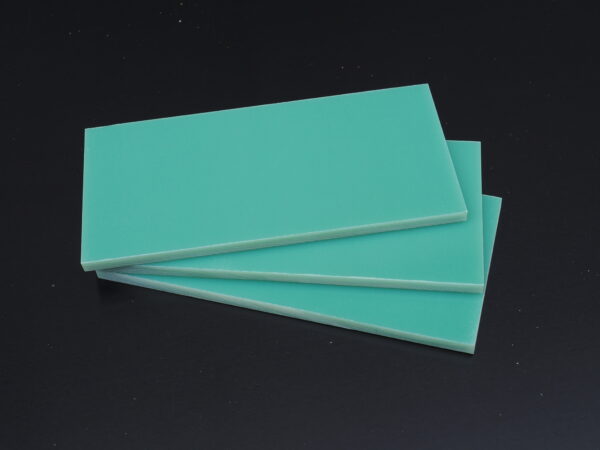

January 10, 2025G-10 FR4 is a high-performance composite material commonly used in the manufacturing of electrical and electronic components. It is a type of fiberglass-reinforced epoxy laminate, known for its excellent strength, durability, and insulation properties. G-10 and FR4 are often used interchangeably, though FR4 refers to the specific grade of the material, which meets certain fire retardant standards.

Composition of G-10 FR4

G-10 FR4 consists of woven fiberglass fabric impregnated with an epoxy resin. The fiberglass provides reinforcement and tensile strength, while the epoxy resin binds the fabric layers together and offers electrical insulating properties. The result is a strong, rigid material that is also lightweight. The “G-10” designation refers to the grade of fiberglass used, which is highly durable and resistant to moisture, chemicals, and heat.

Properties of G-10 FR4

G-10 FR4 boasts several key properties that make it suitable for a range of applications. It has excellent electrical insulating qualities, which makes it ideal for use in printed circuit boards (PCBs) and electrical enclosures. Its high mechanical strength and resistance to temperature fluctuations ensure that G-10 FR4 maintains its integrity in challenging conditions. The material also has low water absorption and is resistant to chemicals, making it durable in harsh environments.

Applications of G-10 FR4

Due to its combination of mechanical, electrical, and thermal properties, G-10 FR4 is widely used in industries such as electronics, aerospace, automotive, and telecommunications. It is commonly found in PCBs, electrical connectors, relay insulators, and structural components for electronic devices.