Is ABS Plastic Expensive?

October 14, 2024

What is Plastic PA6?

October 14, 2024Understanding ABS Plastic

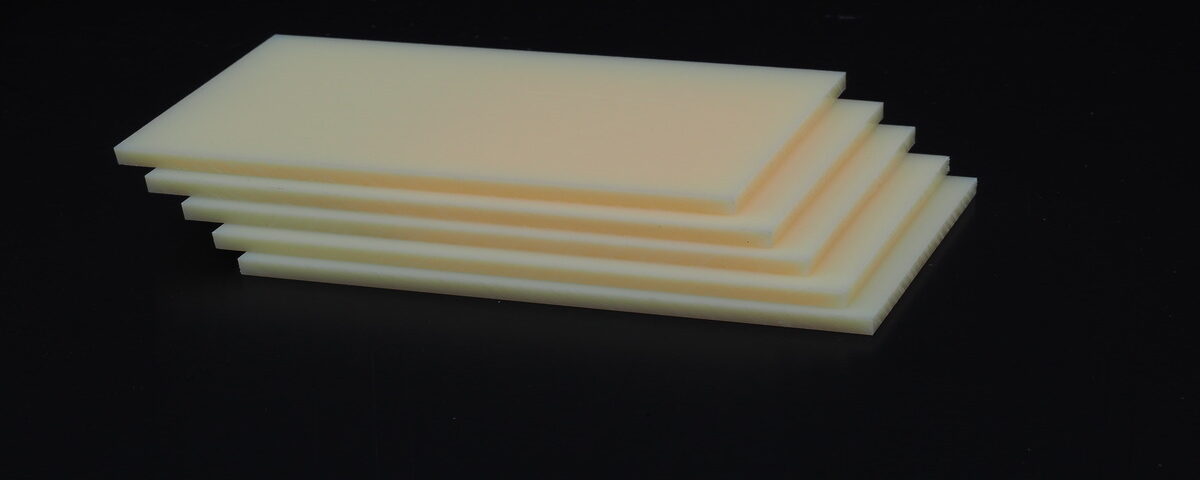

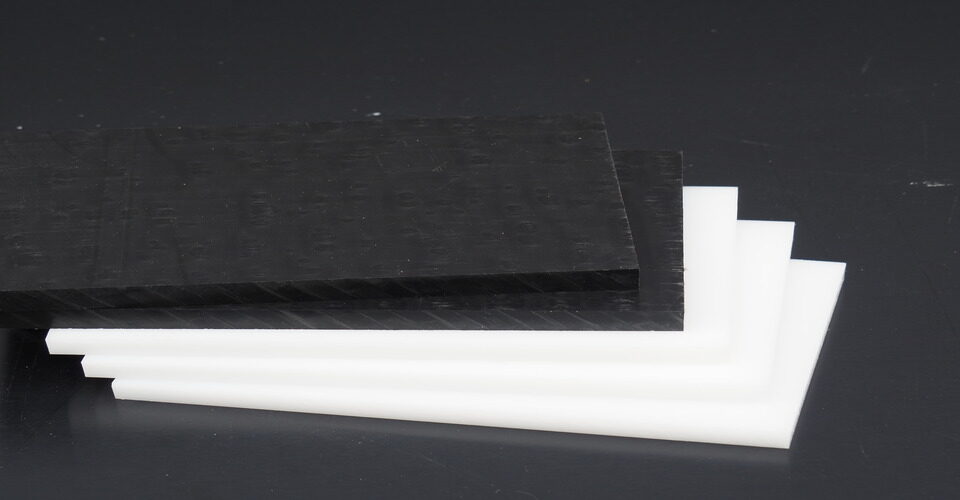

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic known for its strength, durability, and resistance to impact. Commonly found in a variety of products, from toys to automotive components, ABS is favored for its excellent mechanical properties.

Causes of Cracking

Cracks in ABS plastic can occur due to several factors. Environmental Stress: Exposure to extreme temperatures can lead to expansion and contraction, creating stress points. Mechanical Stress: Overloading or applying excessive force can cause fractures. Chemical Exposure: Certain solvents or chemicals can weaken ABS, making it prone to cracking.

Signs of ABS Plastic Crack

Identifying cracks early is crucial for maintaining the integrity of ABS products. Look for visible fissures, surface deformation, or any unusual noise when applying pressure. Discoloration or changes in texture may also indicate underlying damage.

Prevention Tips

To prevent cracking in ABS plastic, consider the following measures:

- Avoid Extreme Conditions: Keep ABS products away from extreme temperatures and direct sunlight.

- Use Proper Handling Techniques: Always lift or carry ABS items properly to minimize stress.

- Choose Compatible Chemicals: When cleaning or maintaining, use products specifically designed for ABS.

Repairing Cracks

Small cracks can often be repaired using adhesives or plastic welding techniques. For larger fractures, consider professional repair services or replacing the item entirely. Regular inspections can help catch issues before they escalate.

Conclusion

Understanding the properties and vulnerabilities of ABS plastic is essential for proper care and maintenance. By recognizing the causes of cracks and implementing preventive measures, you can prolong the life of your ABS products.