PTFE sheet skived machine for PTFE molding

October 31, 2024

High-End Engineering Polyvinylidene Fluoride

October 31, 2024Introduction

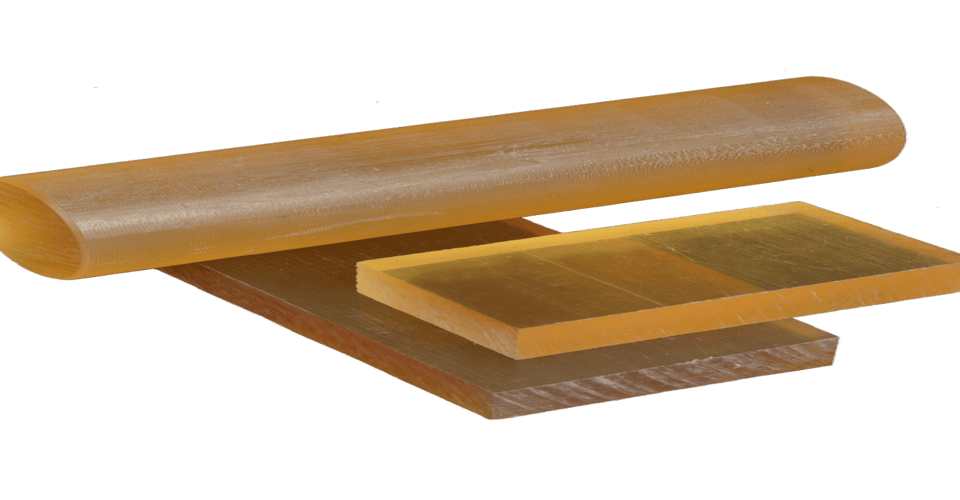

The automatic ram extrusion machine for PTFE rod is a cutting-edge solution tailored for high-volume production. This machine efficiently transforms polytetrafluoroethylene (PTFE) resin into durable rods, widely used across various industries.

Features

High Throughput

Designed for maximum efficiency, the machine can process large quantities of PTFE, significantly reducing production time. Its automatic operation allows for continuous production, meeting demanding manufacturing schedules.

Precision Engineering

Equipped with advanced control systems, the machine ensures consistent dimensions and quality of the extruded rods. This precision is essential in industries requiring exact specifications, such as aerospace and automotive.

User-Friendly Interface

The intuitive control panel makes it easy for operators to adjust settings and monitor the extrusion process. This user-friendly design minimizes training time and enhances operational efficiency.

Applications

Industrial Applications

PTFE rods produced by this machine are used in a variety of industrial applications, including seals, bearings, and gaskets. Their resistance to chemicals and high temperatures makes them ideal for harsh environments.

Medical Uses

In the medical field, PTFE rods are employed for surgical instruments and implants, benefiting from their biocompatibility and low friction properties, which help minimize irritation.

Maintenance

Regular maintenance is vital to ensure optimal performance. The machine is designed for easy access to components, facilitating routine checks and servicing to prevent downtime.

Conclusion

Investing in an automatic ram extrusion machine for PTFE rod production enhances manufacturing capabilities. Its efficiency, precision, and versatility make it a valuable asset for producers aiming to meet diverse industry demands.