How to Make Better-Quality PTFE Gasket?

October 30, 2024

Ram Extrusion Machine for PTFE Sheet

October 30, 2024Introduction

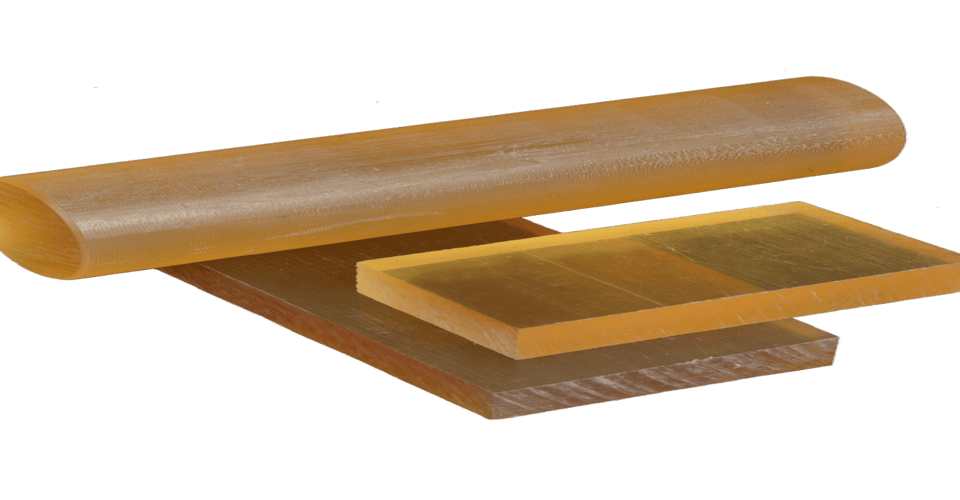

The bronze filled PTFE bush molding machine is an advanced piece of equipment designed for producing high-quality bushings made from a composite of polytetrafluoroethylene (PTFE) filled with bronze particles. This combination enhances the material’s wear resistance and thermal conductivity, making it ideal for demanding industrial applications.

Working Principle

The machine operates by combining bronze-filled PTFE powder with heat and pressure in a mold. Initially, the PTFE powder and bronze filler are mixed and placed into the mold cavity. The machine then applies heat to soften the PTFE and pressure to compact the material, ensuring it takes the shape of the mold. Once cooled, the bushings are ejected, ready for use.

Key Features

- High Pressure System: Capable of exerting significant pressure to ensure thorough molding and high density in the final product.

- Precise Temperature Control: Equipped with advanced heating elements that maintain consistent temperatures for optimal melting and processing.

- Versatile Molding Options: Able to create various shapes and sizes of bushings to meet specific industry requirements.

Applications

Bronze filled PTFE bushings are utilized in numerous applications, including automotive, aerospace, and manufacturing sectors. Their enhanced properties make them suitable for high-load and high-friction environments.

Conclusion

The bronze filled PTFE bush molding machine plays a vital role in the production of durable, high-performance bushings. By leveraging its advanced technology and features, manufacturers can meet the rigorous demands of various industries, ensuring reliability and efficiency in their operations.