What is UHMWPE used for?

October 29, 2024

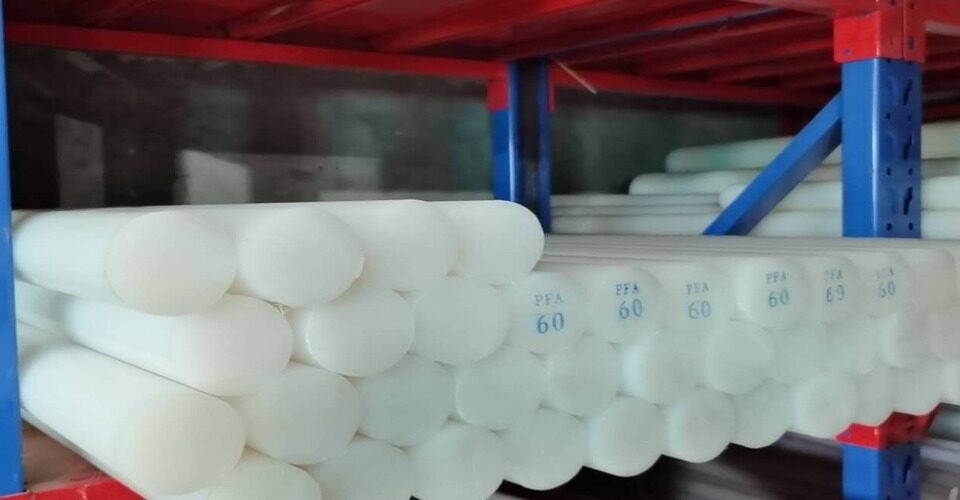

Can PTFE be molded?

October 29, 2024Polytetrafluoroethylene (PTFE) is a well-known fluoropolymer prized for its unique properties, including exceptional chemical resistance and high-temperature stability. A frequent inquiry is whether PTFE can be thermoformed.

Understanding Thermoforming

Thermoforming is a manufacturing process where a thermoplastic sheet is heated until pliable and then shaped over a mold. This technique is commonly used for various materials, but PTFE’s behavior complicates its use in traditional thermoforming methods.

The Nature of PTFE

Unlike conventional thermoplastics, PTFE does not melt; it softens when heated. This characteristic poses challenges for standard thermoforming, as the process relies on the material becoming sufficiently pliable to take on the mold’s shape.

Methods for Thermoforming PTFE

Although PTFE cannot be thermoformed in the traditional sense, specialized techniques allow for its shaping. For example, using a combination of heat and pressure, PTFE can be formed into specific shapes using compression or vacuum forming methods. These processes involve heating PTFE sheets to a point where they can be molded, albeit not as easily as other thermoplastics.

Applications of Thermoformed PTFE

Thermoformed PTFE products are utilized in demanding environments, including chemical processing and electrical insulation. Their ability to withstand extreme conditions makes them suitable for gaskets, seals, and liners.

Conclusion

In conclusion, while PTFE cannot be thermoformed using standard methods, alternative techniques enable its shaping into useful forms, reinforcing its importance in various industrial applications.