What Are the Disadvantages of PMMA Plastic?

December 6, 2024

What is PEI Filament Used For?

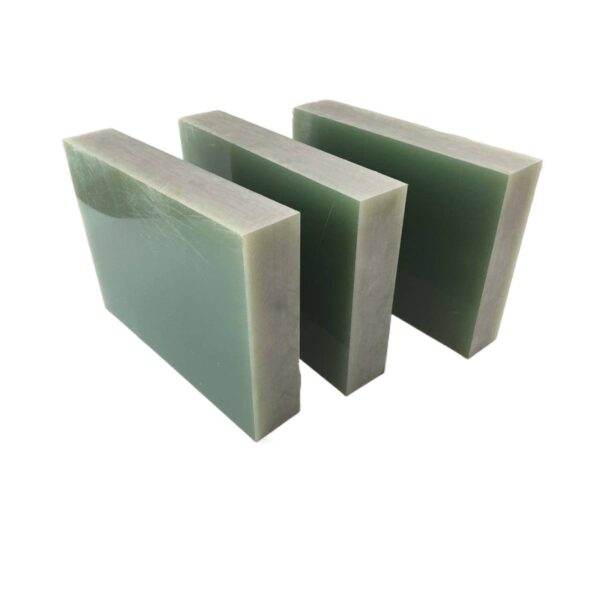

December 9, 2024FR4 is a common designation for a type of fiberglass material widely used in electrical and mechanical applications. It is important to clarify whether FR4 is fiberglass, as the term is often associated with a specific type of composite. Below is an explanation of FR4 and its relationship to fiberglass.

1. FR4 Composition

FR4 is not purely fiberglass, but it is a fiberglass-reinforced plastic. It consists of a base of woven fiberglass cloth that is impregnated with an epoxy resin. This combination gives the material its strength and durability. The “FR” in FR4 stands for “Flame Retardant,” indicating that the resin used in the composition provides fire-resistant properties.

2. Fiberglass Reinforcement

The fiberglass component in FR4 is what provides the material with its rigidity and structural strength. The woven fiberglass cloth serves as the reinforcement, while the epoxy resin binds the fibers together. This reinforcement makes FR4 a much stronger material than regular fiberglass.

3. Properties of FR4

FR4 is known for its excellent electrical insulating properties, high mechanical strength, and resistance to moisture and heat. These attributes make it an ideal choice for manufacturing printed circuit boards (PCBs), as well as in other electrical and industrial applications. Unlike plain fiberglass, FR4 is more versatile and engineered for specific functional properties.

4. Applications of FR4

FR4 is primarily used in electronics, particularly for PCB substrates, as well as in applications requiring high mechanical strength, thermal stability, and electrical insulation. While fiberglass alone is used in some applications, FR4’s enhanced performance characteristics make it preferred in demanding environments.

In conclusion, while FR4 contains fiberglass, it is not the same as pure fiberglass. It is a fiberglass-reinforced epoxy material with specific properties tailored for specialized applications.