Who Makes PCTFE?

October 21, 2024

What is a PTFE Gasket?

October 22, 2024Introduction

The PTFE ram extrusion machine is a specialized piece of equipment designed for the manufacturing of polytetrafluoroethylene (PTFE) products. This machine utilizes a ram-type system to create precise shapes and dimensions, making it essential in various industries, including aerospace, automotive, and chemical processing.

Working Principle

The machine operates by pushing PTFE material through a die using a hydraulic ram. The process involves heating the PTFE to a pliable state before it is extruded. This allows for the creation of complex shapes, ensuring consistency and quality in the final product.

Advantages

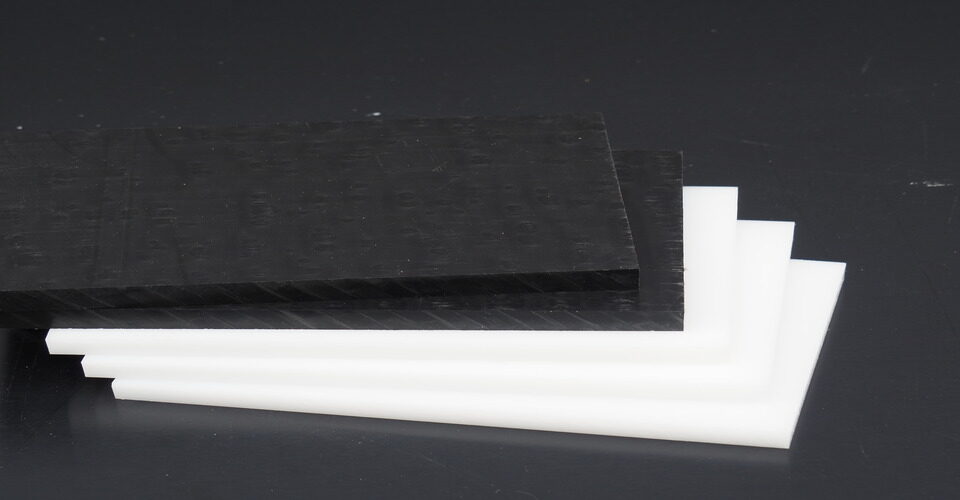

One of the primary advantages of the PTFE ram extrusion machine is its ability to produce high-quality components with minimal waste. The machine offers excellent control over the extrusion process, resulting in uniform density and improved mechanical properties. Additionally, it can handle various grades of PTFE, enhancing versatility in production.

Applications

PTFE ram extrusion machines are widely used in producing seals, gaskets, tubing, and other components that require high-temperature resistance and chemical stability. Their application in industries such as electronics, pharmaceuticals, and food processing underscores their importance.

Maintenance

Regular maintenance of the PTFE ram extrusion machine is crucial for optimal performance. This includes routine cleaning, inspection of hydraulic systems, and replacement of worn components to prevent downtime and ensure efficiency.

Conclusion

In summary, the PTFE ram extrusion machine plays a vital role in the manufacturing of PTFE products. Its efficiency, precision, and versatility make it indispensable in modern industrial applications.