PTFE bar ram extrusion machine

October 30, 2024

How to Make Better-Quality PTFE Gasket?

October 30, 2024Introduction

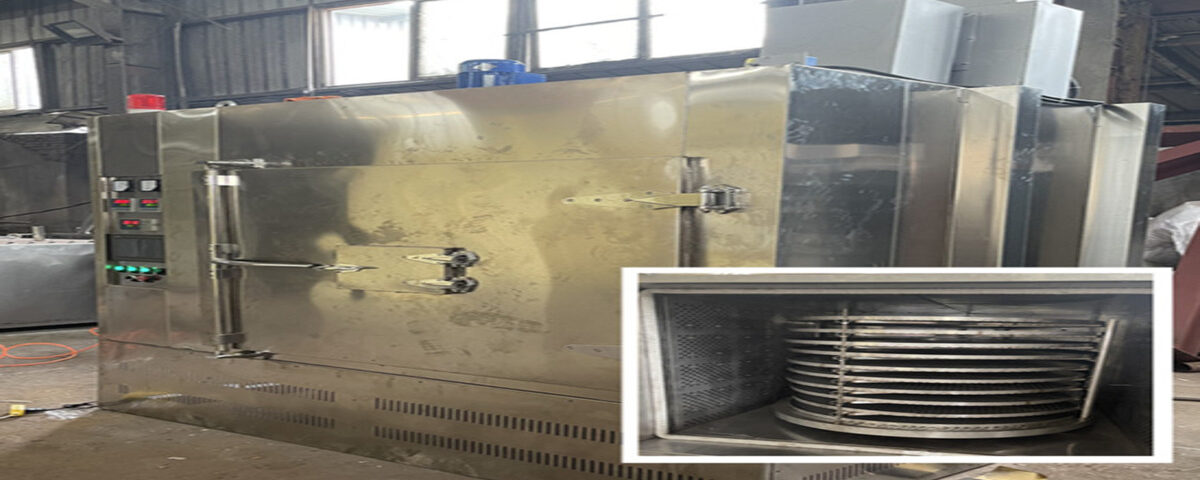

The PTFE rotation sintering oven is a critical piece of equipment designed for processing PTFE (polytetrafluoroethylene) materials. As an essential tool in the manufacturing of high-performance components, this oven is now prepared for shipment, ensuring timely delivery to clients.

Features

- Rotational Design: The oven’s unique rotation mechanism ensures uniform heating and sintering of PTFE products, enhancing their mechanical properties and dimensional stability.

- Advanced Temperature Control: Equipped with precise temperature control systems, the oven can maintain consistent heat, vital for effective sintering processes.

- Energy Efficiency: Designed with energy-saving features, this oven minimizes operational costs while maximizing productivity.

Benefits

Using a PTFE rotation sintering oven provides several advantages, including:

- Improved Quality: The uniform heating process reduces defects, resulting in high-quality finished products.

- Versatility: Suitable for various PTFE components, making it adaptable to different manufacturing needs.

- Reduced Cycle Time: The efficient design allows for quicker processing times, enabling faster production rates.

Preparation for Shipment

Before shipping, the oven undergoes thorough quality checks to ensure it meets all specifications. Each unit is carefully packaged to prevent damage during transit, and all necessary documentation is provided to facilitate a smooth delivery process.

Conclusion

The PTFE rotation sintering oven is ready for shipment, poised to enhance the production capabilities of its new owner. With its advanced features and benefits, this oven represents a valuable investment for businesses looking to optimize their PTFE manufacturing processes.