Is PVC and ABS Plastic?

November 28, 2024

Is FEP the same as Teflon?

November 29, 2024ABS (Acrylonitrile Butadiene Styrene) plastic is a widely used thermoplastic known for its diverse properties that make it suitable for various applications. It is a blend of three monomers: acrylonitrile, butadiene, and styrene, each contributing unique characteristics to the material.

Strength and Durability

One of the most important properties of ABS plastic is its impressive strength and durability. It is resistant to impact and can withstand physical stress, making it ideal for applications where toughness is essential. ABS maintains its integrity even in challenging environments.

Chemical Resistance

ABS plastic offers moderate resistance to a range of chemicals, including acids and alkalis, which makes it suitable for use in various industries such as automotive and electronics. However, it is not resistant to some strong solvents, so careful consideration is needed when exposed to certain chemicals.

Thermal Resistance

ABS can endure high temperatures up to 100°C (212°F) before it starts to deform. It has a relatively low thermal expansion, which makes it useful in applications where temperature fluctuations occur.

Easy to Process

ABS plastic is easily molded and shaped, which makes it ideal for injection molding and 3D printing. It also has good bonding properties and can be glued, painted, or welded, offering flexibility in design and manufacturing.

Electrical Insulation

ABS is an excellent electrical insulator, adding to its versatility in electronics and electrical applications. This property allows it to be used in housings for electrical components.

Aesthetic Appeal

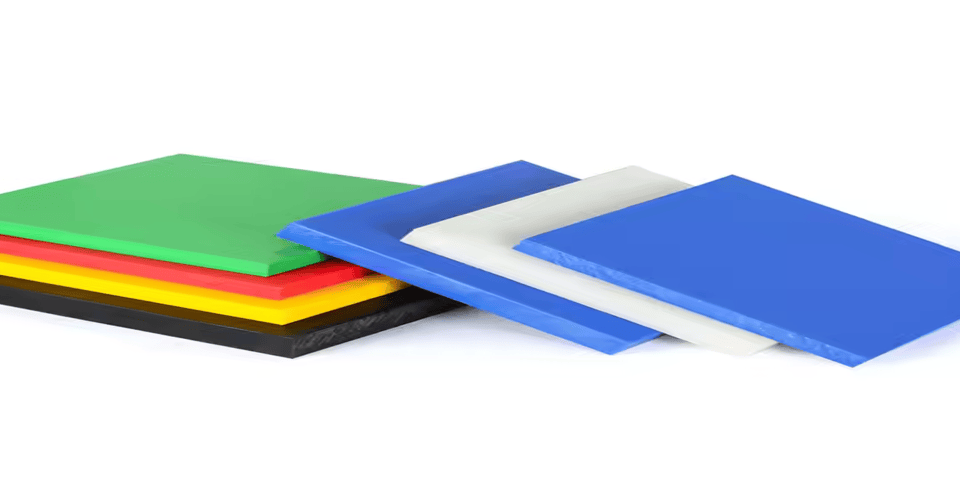

ABS plastic can be finished in a smooth, glossy surface, allowing it to be used in consumer products like toys, automotive parts, and household appliances. It can also be colored easily, making it highly customizable.