Is Bakelite a metal, ceramic, or polymer?

January 10, 2025

What are the properties of polyvinyl fluoride?

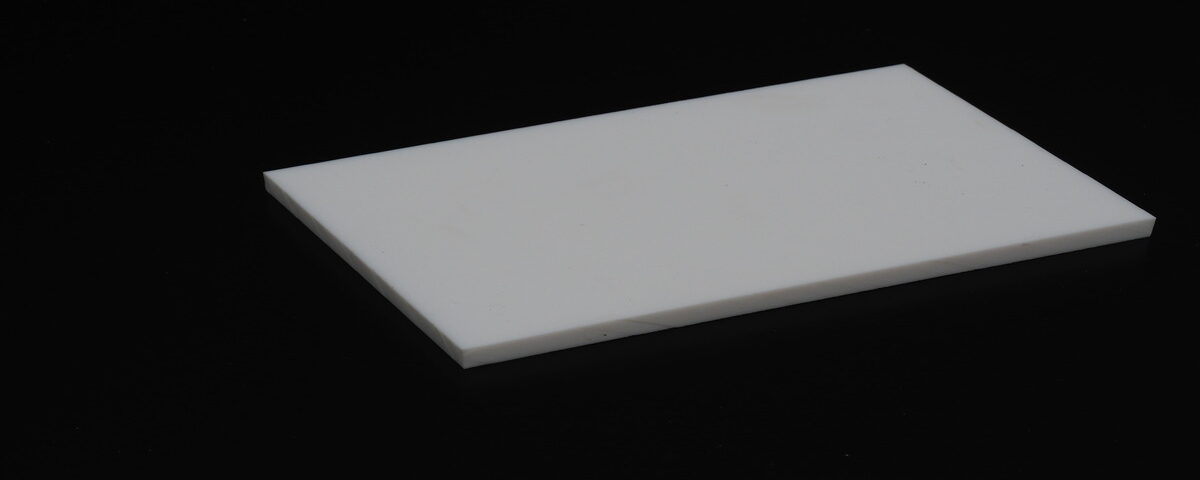

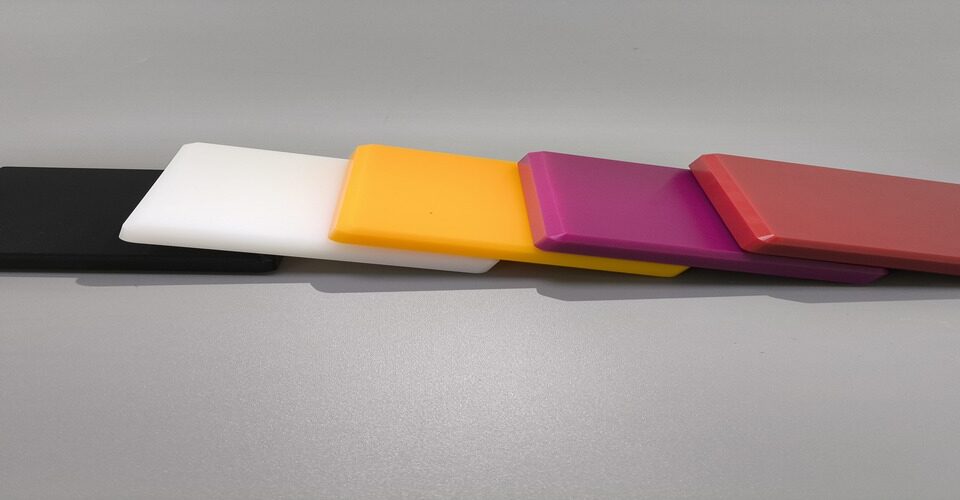

January 13, 2025PTFE (Polytetrafluoroethylene) is a high-performance plastic material that exhibits exceptional properties, making it ideal for a wide range of industrial applications. PTFE sheets, made from this versatile polymer, are used in various fields, such as electrical, chemical, and manufacturing industries. Below are the key properties of PTFE sheets:

1. High Thermal Resistance PTFE sheets can withstand high temperatures, with a continuous operating temperature range from -200°C to +260°C. This makes them suitable for applications involving extreme heat, such as insulation in electrical cables or seals in high-temperature environments.

2. Chemical Resistance PTFE is known for its outstanding resistance to chemicals, acids, and solvents. It is nearly inert to all chemicals, including strong acids and bases, which makes it an ideal choice for use in corrosive environments, like in the chemical processing industry.

3. Low Friction Coefficient One of the most notable properties of PTFE is its low friction coefficient. PTFE sheets exhibit excellent non-stick characteristics, which minimize wear and reduce friction between surfaces. This property is beneficial in applications like bearings, seals, and gaskets.

4. Electrical Insulation PTFE has excellent dielectric properties, meaning it is a superb electrical insulator. PTFE sheets are often used in electrical and electronic applications to insulate wiring and components, providing reliable performance in high-voltage environments.

5. Non-Toxicity PTFE sheets are non-toxic and safe for food contact, which makes them suitable for use in the food processing and pharmaceutical industries. They do not leach harmful substances, ensuring a safe and clean environment.

In conclusion, PTFE sheets are highly valued for their durability, resistance to heat and chemicals, low friction, and electrical insulating properties.