PTFE Ram Extrusion Machine

October 22, 2024

HDPE Plastic Sheets

October 22, 2024Introduction

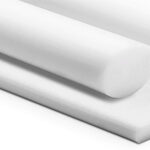

A PTFE gasket is a sealing component made from polytetrafluoroethylene (PTFE), a high-performance plastic known for its exceptional chemical resistance and thermal stability. PTFE gaskets are widely used in various industries due to their ability to withstand extreme conditions.

Properties

PTFE gaskets are characterized by their low friction, high tensile strength, and non-stick properties. They can operate effectively at temperatures ranging from -200°C to 260°C (-328°F to 500°F), making them suitable for both cryogenic and high-heat applications. Additionally, PTFE is chemically inert, resisting most solvents, acids, and bases.

Applications

These gaskets are commonly used in industries such as oil and gas, pharmaceuticals, food processing, and chemical manufacturing. PTFE gaskets provide reliable sealing in flanged joints, valves, pumps, and heat exchangers, ensuring leak-proof operations and maintaining system integrity.

Benefits

One of the main benefits of PTFE gaskets is their durability. They resist wear and tear, reducing the frequency of maintenance and replacements. Their excellent compressibility and adaptability to irregular surfaces help in creating effective seals even under challenging conditions.

Installation

Installing a PTFE gasket requires careful attention to the surface preparation and alignment. Proper installation ensures optimal sealing performance and longevity. It is essential to avoid over-tightening, which can damage the gasket.

Conclusion

In summary, PTFE gaskets are vital components that offer outstanding performance in sealing applications. Their unique properties and versatility make them an ideal choice for demanding environments.