What is Bakelite Used For?

November 1, 2024

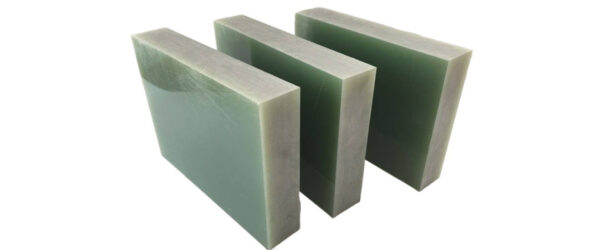

What is FR4 Plastic?

November 1, 2024FR4 is a widely used composite material primarily known for its electrical insulating properties and mechanical strength. It is a type of fiberglass-reinforced epoxy laminate, making it a versatile choice in various applications.

Composition

FR4 is composed of woven fiberglass fabric impregnated with epoxy resin. This combination provides exceptional strength and rigidity, making it suitable for demanding environments. The “FR” in FR4 stands for “flame retardant,” indicating its ability to resist combustion.

Electrical Insulation

One of the key features of FR4 is its excellent electrical insulating properties. It is commonly used in the manufacturing of printed circuit boards (PCBs) due to its low dielectric constant and dissipation factor. This makes it ideal for electronic applications, where reliable insulation is crucial.

Thermal Properties

FR4 can withstand high temperatures, typically up to 130°C (266°F), without losing its structural integrity. This heat resistance makes it suitable for applications involving high heat, such as in electrical and electronic devices.

Applications

Beyond PCBs, FR4 is used in a variety of industries, including telecommunications, aerospace, and automotive. It is found in components such as connectors, insulators, and various electronic devices, contributing to their overall reliability and performance.

Environmental Resistance

FR4 also offers good resistance to moisture, chemicals, and other environmental factors, enhancing its durability in harsh conditions.

Conclusion

In summary, FR4 material is a robust and versatile composite that excels in electrical insulation, thermal resistance, and environmental durability, making it a preferred choice in many engineering and manufacturing applications.