What is the Material for PI?

December 17, 2024

What is the Full Form of PAI in Plastic Material?

December 18, 2024PEEK (Polyether Ether Ketone) is a high-performance thermoplastic polymer known for its outstanding mechanical properties, thermal stability, and chemical resistance. The composition of PEEK plastic is what makes it suitable for use in extreme environments, including aerospace, medical, and automotive industries.

Chemical Structure of PEEK

PEEK plastic is primarily made of repeating units of ether (–O–) and ketone (–CO–) functional groups, which are bonded to aromatic hydrocarbon rings. This structure gives PEEK its high strength, stiffness, and resistance to wear and corrosion. The polymer is synthesized by the polymerization of 4,4′-difluorobenzophenone with hydroquinone in the presence of a strong base.

Key Components in PEEK

The main components that make up PEEK are:

- Aromatic Rings: These provide rigidity and stability to the polymer.

- Ether Groups: These enhance the polymer’s flexibility and resistance to hydrolysis and high temperatures.

- Ketone Groups: The ketone linkages offer PEEK its high thermal resistance and mechanical strength.

The combination of these functional groups results in a polymer chain that is both chemically stable and thermally resistant, making PEEK an ideal material for high-performance applications.

Processing of PEEK

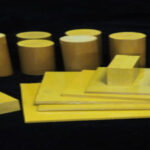

PEEK is typically processed through methods such as extrusion, injection molding, or compression molding. These techniques allow it to be formed into complex shapes and structures suitable for industrial use.

Conclusion

In summary, PEEK plastic is made of aromatic ether and ketone units, which give it exceptional strength, thermal stability, and chemical resistance. Its unique composition makes it a preferred choice for demanding applications in various industries.