What is the material for PE?

January 9, 2025

what is the overview of psu material?

January 9, 2025Polyurethane is a versatile polymer commonly used in the production of flexible and rigid foams, coatings, adhesives, and elastomers. It is created through a chemical reaction between two key ingredients: polyols and isocyanates.

The Chemical Composition of Polyurethane

Polyurethane is synthesized by combining polyols (alcohol-based compounds with multiple hydroxyl groups) with isocyanates (organic compounds containing an isocyanate group, -NCO). This reaction is known as polyaddition. The polyol provides the backbone for the polymer, while the isocyanate contributes to the crosslinking, forming the structure of the polyurethane. This combination results in a highly durable and flexible material.

Types of Polyurethane

There are two primary categories of polyurethane, each with distinct properties:

- Flexible Polyurethane: This type of polyurethane is used to make soft, cushioned products such as mattresses, furniture, and automotive seating. It is characterized by its ability to absorb shock and provide comfort.

- Rigid Polyurethane: Rigid polyurethane is commonly used in insulation materials, structural foams, and adhesives. It has a solid, firm structure, offering excellent thermal insulation and durability.

Additives in Polyurethane

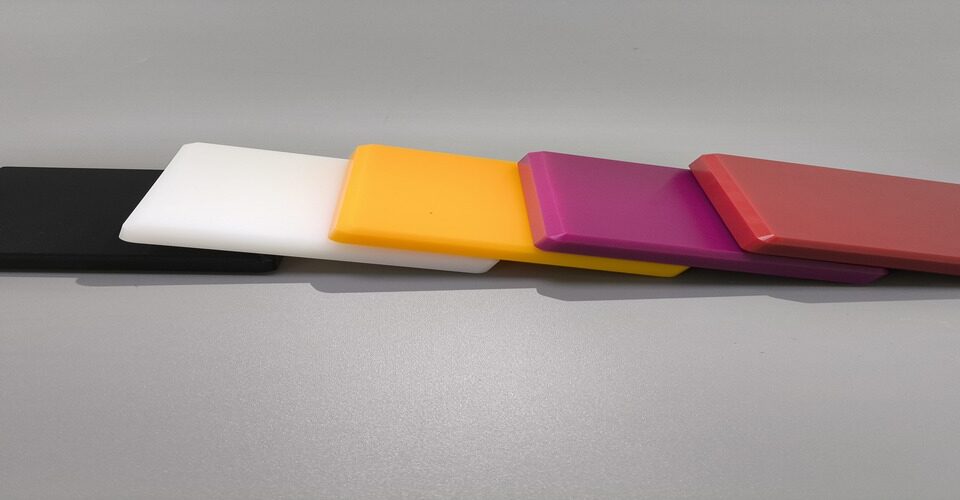

Various additives can be incorporated into polyurethane to enhance its properties. These include flame retardants, plasticizers, stabilizers, and colorants, which modify characteristics like fire resistance, flexibility, and appearance.

Key Properties of Polyurethane

Polyurethane is known for its strength, durability, flexibility, and resistance to wear and tear. It is also resistant to moisture, oils, and solvents, making it suitable for a wide range of industrial and consumer applications.

In conclusion, polyurethane is primarily made from polyols and isocyanates, with the final properties depending on the specific formulation and type used.