What is PEEK in Fabric?

December 13, 2024

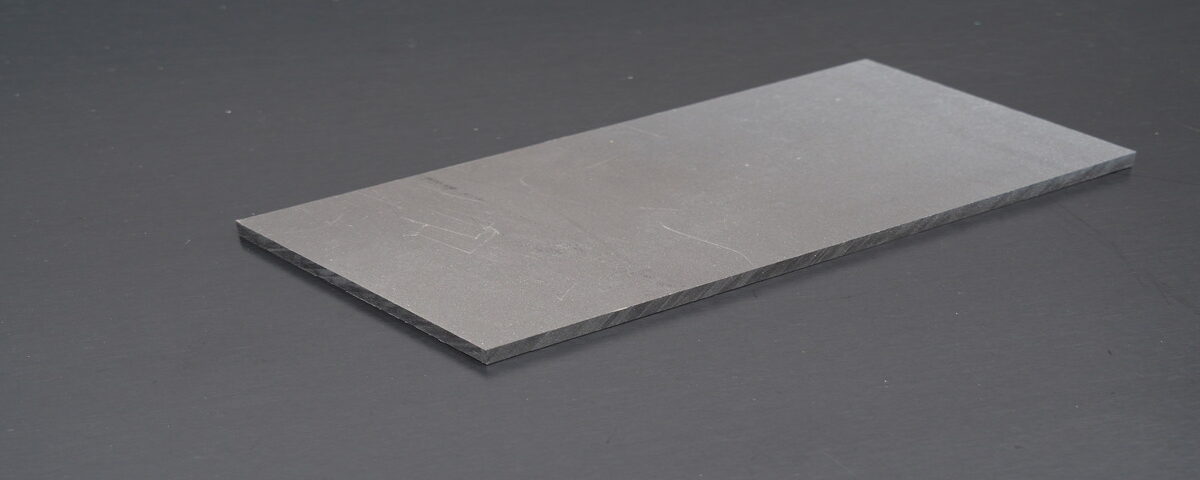

What is PVDF material used for?

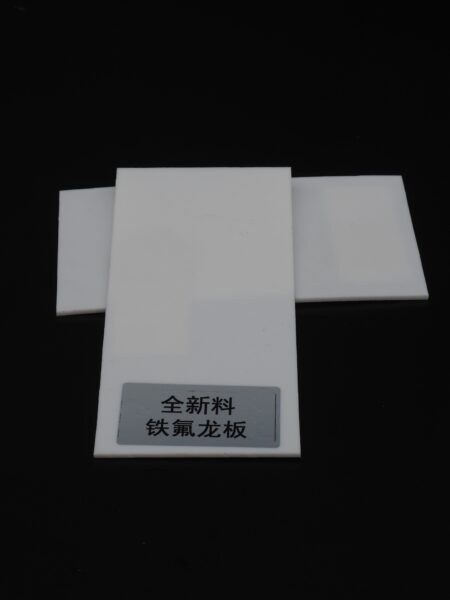

December 16, 2024PTFE (Polytetrafluoroethylene) film is a versatile material known for its exceptional chemical resistance, high-temperature stability, and non-stick properties. This film is used in various industrial and commercial applications due to its unique characteristics. PTFE film is made from a synthetic polymer that is widely used in fields requiring reliable, long-lasting materials.

Applications of PTFE Film

One of the most common uses of PTFE film is in the electronics industry, where it serves as an insulation material for wiring and cables. Its excellent dielectric properties make it ideal for electrical and electronic applications, especially where high temperatures are involved. PTFE film is also used as a protective liner in the food processing industry, where its non-stick properties prevent materials from adhering to surfaces. Additionally, PTFE films are commonly used in medical devices such as catheters, wound dressings, and implants due to their biocompatibility and resistance to bacteria.

Benefits of PTFE Film

PTFE film offers numerous benefits, such as high chemical resistance, making it ideal for use in aggressive environments where other materials might degrade. It also provides outstanding thermal stability, maintaining its integrity in extreme temperatures ranging from -450°F to 500°F (-268°C to 260°C). Furthermore, PTFE film has low friction and is non-reactive, which is why it is used in non-stick coatings and lubrication applications.

Conclusion

In summary, PTFE film is an essential material used in a variety of industries due to its unmatched chemical resistance, temperature stability, and non-stick properties. It plays a vital role in the electronics, food, medical, and manufacturing sectors, ensuring performance and longevity in demanding environments.