Which is better, PTFE or PVDF?

January 17, 2025

Where is PU Sheet used?

January 17, 2025PTFE (Polytetrafluoroethylene) and PVC (Polyvinyl Chloride) are both widely used synthetic polymers, but they have distinct properties, uses, and manufacturing processes. Understanding the differences between these two materials is essential for selecting the right material for specific applications.

Chemical Composition and Structure

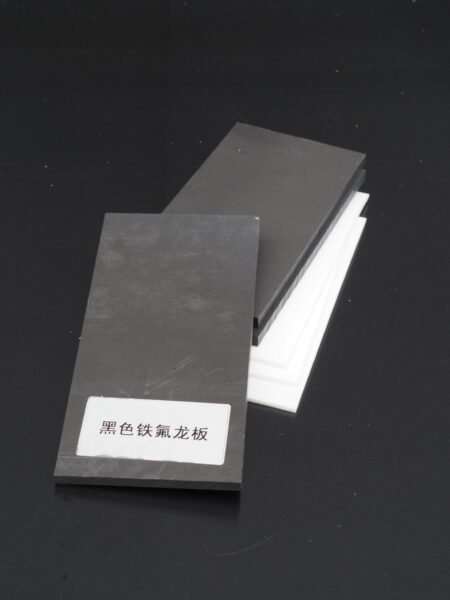

PTFE is a fluoropolymer made from tetrafluoroethylene monomers. It has a carbon backbone bonded to fluorine atoms, which gives it exceptional chemical resistance and high-temperature stability. PVC, on the other hand, is made from vinyl chloride monomers. It consists of a polymer chain with chlorine atoms attached to the carbon backbone, making it rigid or flexible depending on additives.

Thermal Properties

PTFE has an outstanding heat resistance, capable of withstanding temperatures up to 260°C (500°F) without degrading. It also remains stable at low temperatures. PVC has lower heat resistance, generally tolerating temperatures up to 60°C to 80°C (140°F to 176°F) before it starts to soften or lose structural integrity.

Mechanical Properties

PTFE is known for its low friction, high flexibility, and non-stick characteristics. It is also highly resistant to wear and tear. PVC is generally rigid but can be made flexible with plasticizers. It is more durable under pressure but lacks the flexibility and low friction qualities of PTFE.

Applications

PTFE is commonly used in applications that require chemical resistance, non-stick surfaces, or high-temperature resistance, such as gaskets, seals, and coatings. PVC, being more cost-effective and versatile, is used in plumbing, electrical insulation, flooring, and medical devices.

Conclusion

Both PTFE and PVC have unique properties making them suitable for specific industrial and commercial applications. The choice between them depends on factors like chemical exposure, temperature resistance, flexibility, and cost considerations.