Can PA plastic be recycled?

December 4, 2024

Is PET Plastic Safe for Humans?

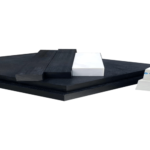

December 4, 2024The full form of UPE material is Ultra-High Molecular Weight Polyethylene. UPE is a type of polyethylene that has an extremely high molecular weight, which gives it unique properties, making it suitable for demanding applications in various industries.

Key Properties of UPE Material

UPE has several remarkable properties due to its high molecular weight:

- High Wear Resistance: UPE is known for its exceptional resistance to abrasion, making it ideal for applications that involve heavy wear and tear, such as in conveyor systems and bearings.

- Low Friction: The material has a very low coefficient of friction, allowing for smooth and efficient movement in applications like sliding components and bushings.

- Chemical Resistance: UPE is highly resistant to chemicals, including acids, alkalis, and solvents, making it suitable for use in harsh chemical environments.

- Impact Strength: UPE is also known for its excellent impact resistance, even at low temperatures, making it useful in high-stress applications.

- Non-Stick Surface: Its low surface energy gives UPE non-stick properties, reducing the buildup of materials on surfaces.

Applications of UPE Material

Due to its superior properties, UPE is widely used in various industries:

- Medical: For implants, surgical instruments, and prosthetics due to its biocompatibility and wear resistance.

- Mining and Material Handling: UPE is used in applications like liners for hoppers and chutes, as it resists abrasion and minimizes friction.

- Food Processing: UPE’s non-stick properties make it ideal for use in food processing equipment