How does PTFE work?

February 24, 2025

What is the difference between ABS and POM material?

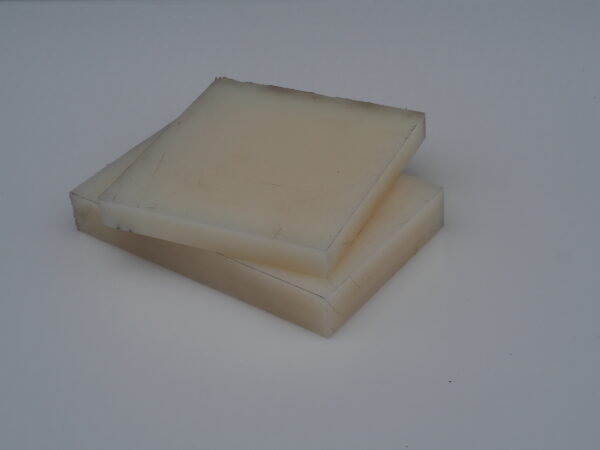

February 24, 2025Polyvinylidene fluoride (PVDF) is a high-performance thermoplastic polymer. PVDF sheets are used in a variety of industries due to their outstanding chemical resistance, durability, and electrical insulating properties.

Key Functions of PVDF Sheet

- Chemical Resistance: One of the primary functions of PVDF sheets is their excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for use in chemical processing equipment, tanks, and piping systems.

- Durability and Strength: PVDF sheets are known for their mechanical strength and ability to withstand harsh environments. They are resistant to wear, making them suitable for applications where materials are exposed to physical stress or abrasion.

- Electrical Insulation: PVDF is an excellent electrical insulator. PVDF sheets are commonly used in electrical and electronic applications where high insulation properties are required.

- UV and Weather Resistance: PVDF is also resistant to ultraviolet (UV) radiation and weathering, which makes it ideal for outdoor applications. It is often used in roofing membranes and other outdoor structures exposed to the elements.

- Flame Retardant: PVDF has inherent flame-retardant properties, which enhances safety in applications involving potential fire hazards, such as in the aerospace and automotive industries.

Applications of PVDF Sheets

PVDF sheets are used in a variety of industries, including:

- Chemical Industry: For tanks, pipes, and valves.

- Electrical Industry: For insulation in wiring and components.

- Construction: In roofing materials and outdoor panels.

Conclusion

The function of PVDF sheets lies in their superior resistance to chemicals, strength, electrical insulation properties, and durability. These characteristics make them essential for use in demanding industrial and commercial applications.