What is HDPE Sheets Used For?

December 11, 2024

What is the Use of PU Foam Sheet?

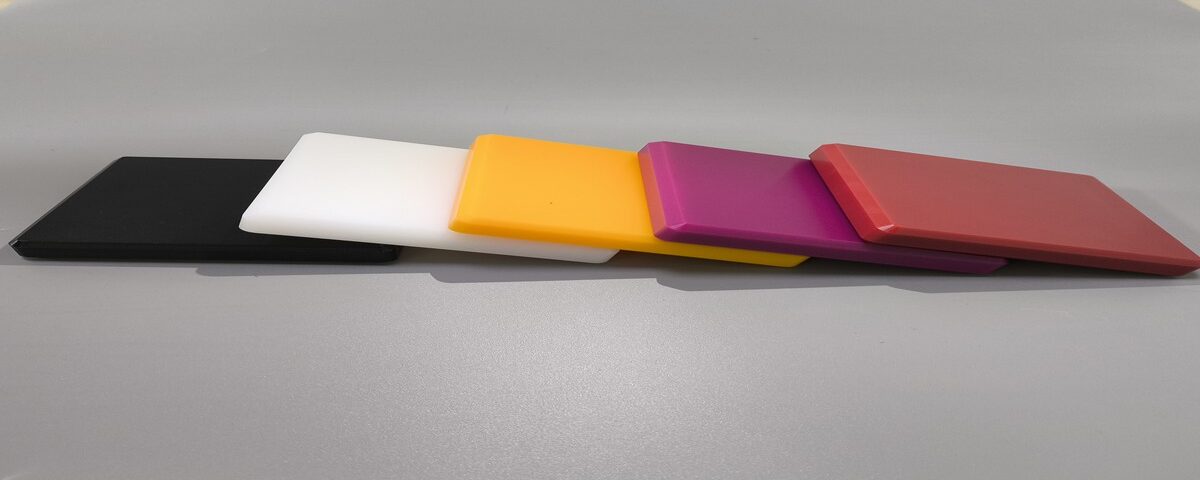

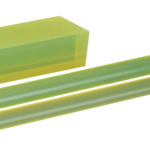

December 11, 2024UPE (Ultra-High Molecular Weight Polyethylene) is a high-performance thermoplastic polymer known for its exceptional properties. UPE is a type of polyethylene with a very high molecular weight, typically ranging from 3 to 6 million g/mol, which gives it superior strength, wear resistance, and durability compared to other polyethylene materials.

Properties of UPE

UPE is renowned for its outstanding resistance to wear and abrasion, making it ideal for applications that involve heavy-duty use and friction. It has a low coefficient of friction, which contributes to its ability to reduce wear and tear on surfaces. Additionally, UPE is chemically resistant and can withstand exposure to a wide range of chemicals, including acids, alkalis, and solvents. It also has excellent impact resistance and can maintain its mechanical properties over a wide range of temperatures, from cryogenic to elevated temperatures.

Common Applications of UPE

Due to its superior properties, UPE is used in a variety of demanding applications. It is commonly used in the mining, material handling, and food processing industries for components such as wear plates, liners, and chutes. Its low friction and abrasion resistance make it ideal for conveyors and machinery parts that experience continuous movement or contact. UPE is also used in medical and pharmaceutical applications for implants and devices due to its biocompatibility and resistance to chemicals.

Benefits of UPE

The benefits of UPE include its long service life, reduced maintenance costs, and increased efficiency in applications that require high wear resistance. Its ability to withstand extreme conditions makes it a go-to material for industries where performance and longevity are critical.

Conclusion

In conclusion, UPE (Ultra-High Molecular Weight Polyethylene) is a highly durable and versatile material used in a wide range of industries. Its unique properties, including wear resistance, chemical stability, and low friction, make it ideal for demanding applications.