What is the CNC Plastic?

October 9, 2024

What is PPS Plastic?

October 9, 2024CNC machining utilizes various plastics, each selected for specific properties and applications. Understanding the characteristics of these materials is essential for achieving optimal results in CNC processes.

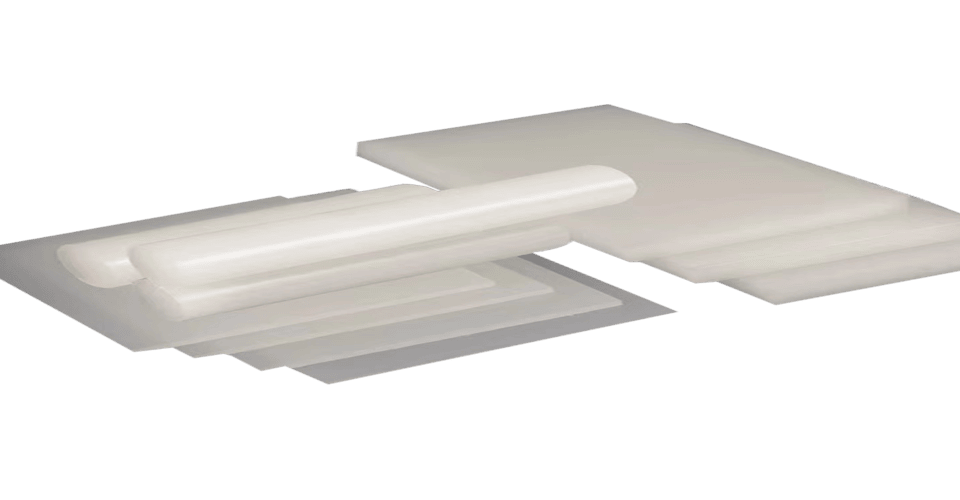

Common Plastics in CNC Machining

- Acrylic (PMMA): Acrylic is favored for its clarity and aesthetic appeal. It’s often used in signs, displays, and protective barriers. Its ease of machining allows for intricate designs, but care must be taken to avoid cracking during processing.

- Polycarbonate: Known for its high impact resistance, polycarbonate is used in safety equipment, lenses, and light fixtures. While more challenging to machine than acrylic, its durability makes it a reliable choice for demanding applications.

- Nylon: This versatile plastic is known for its strength, flexibility, and wear resistance. It’s commonly used in gears, bearings, and other mechanical parts. Nylon can absorb moisture, which may affect its dimensional stability, so considerations for humidity are important during machining.

- PTFE (Teflon): PTFE is highly resistant to chemicals and has excellent non-stick properties. It’s used in applications where low friction is required, such as seals and gaskets. Machining PTFE requires specialized tools due to its softness and tendency to deform.

- Acetal (POM): Acetal is prized for its low friction and high strength, making it suitable for precision components. Its machinability and stability under load make it a popular choice in engineering applications.

Conclusion

Selecting the right plastic for CNC machining involves considering the specific needs of your project, including mechanical properties, environmental factors, and machining capabilities.