why peek sheet is used in industry?

February 21, 2025When choosing between ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride) plastic sheets, both materials offer unique advantages depending on the intended application. Let’s explore the key differences and benefits of each.

1. Durability and Strength

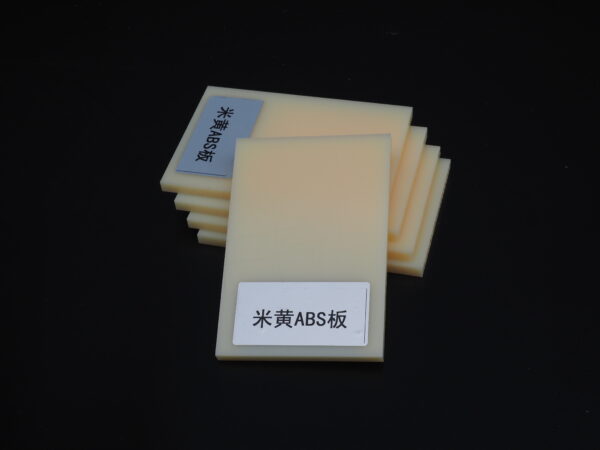

- ABS: Known for its toughness and impact resistance, ABS is more durable and can withstand higher stress and strain. It is less likely to crack under impact.

- PVC: While PVC is fairly strong, it is more brittle than ABS, especially under low temperatures. It can crack or break when exposed to sudden impact.

2. Chemical Resistance

- ABS: ABS has good resistance to oils, greases, and certain acids but can degrade when exposed to harsh chemicals like concentrated acids or alkalis.

- PVC: PVC excels in resisting a wider range of chemicals, including acids, bases, and salts. It’s a preferred choice for plumbing and chemical processing applications.

3. Ease of Fabrication

- ABS: ABS sheets are easy to machine, drill, and glue, making them ideal for applications that require custom fabrication.

- PVC: PVC is also easy to cut, shape, and weld, though it may not be as versatile in some specific fabrication processes like ABS.

4. Temperature Resistance

- ABS: It offers a moderate temperature resistance of up to around 90°C (194°F) before softening or losing shape.

- PVC: PVC typically has a lower temperature resistance, withstanding around 60°C (140°F), making it unsuitable for high-temperature applications.

5. Aesthetic Appeal

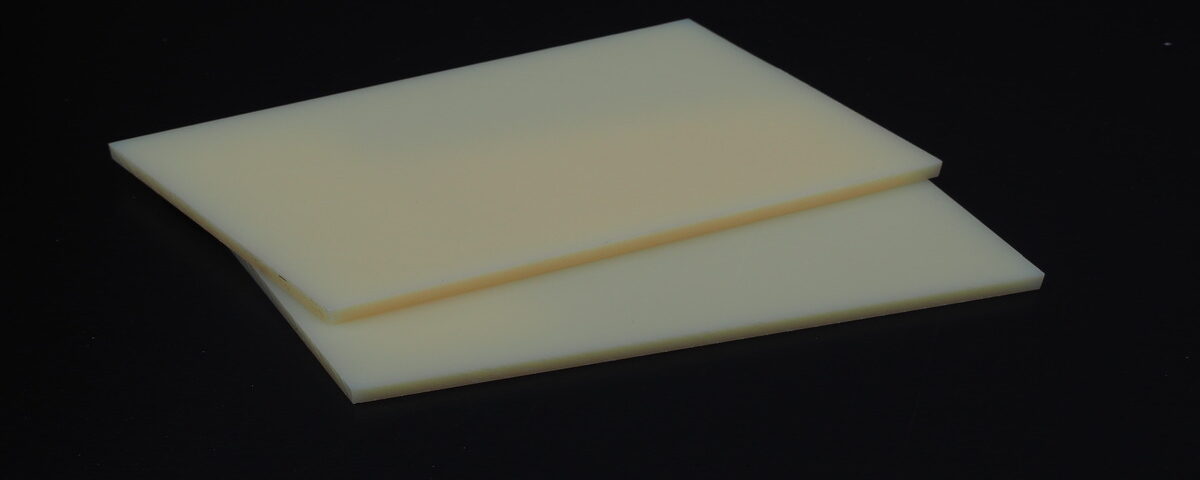

- ABS: ABS is available in a wide range of colors and finishes, making it suitable for aesthetic applications like consumer products and automotive parts.

- PVC: PVC can also be available in various colors but often lacks the glossy finish of ABS, making it less suitable for aesthetic purposes.

6. Cost

- ABS: Typically, ABS sheets tend to be more expensive than PVC sheets due to their enhanced durability and aesthetic quality.

- PVC: PVC sheets are generally more affordable, making them a cost-effective option for industrial applications.

Conclusion

The choice between ABS and PVC depends on the specific requirements of the project. ABS is better for durability, impact resistance, and aesthetic needs, while PVC excels in chemical resistance, cost-effectiveness, and ease of fabrication.